Krenhof

A member of the Pankl Group

With more than 300 years of expertise, Krenhof is the leading forging competence center in Europe. The automotive, aerospace and construction industries rely on our high-quality components. That is why more than 22,000 tons of steel and 3,000 tons of aluminum are processed every year and delivered to well-known customers. We can do this because together we get a little bit better every day.

Contact: [email protected]

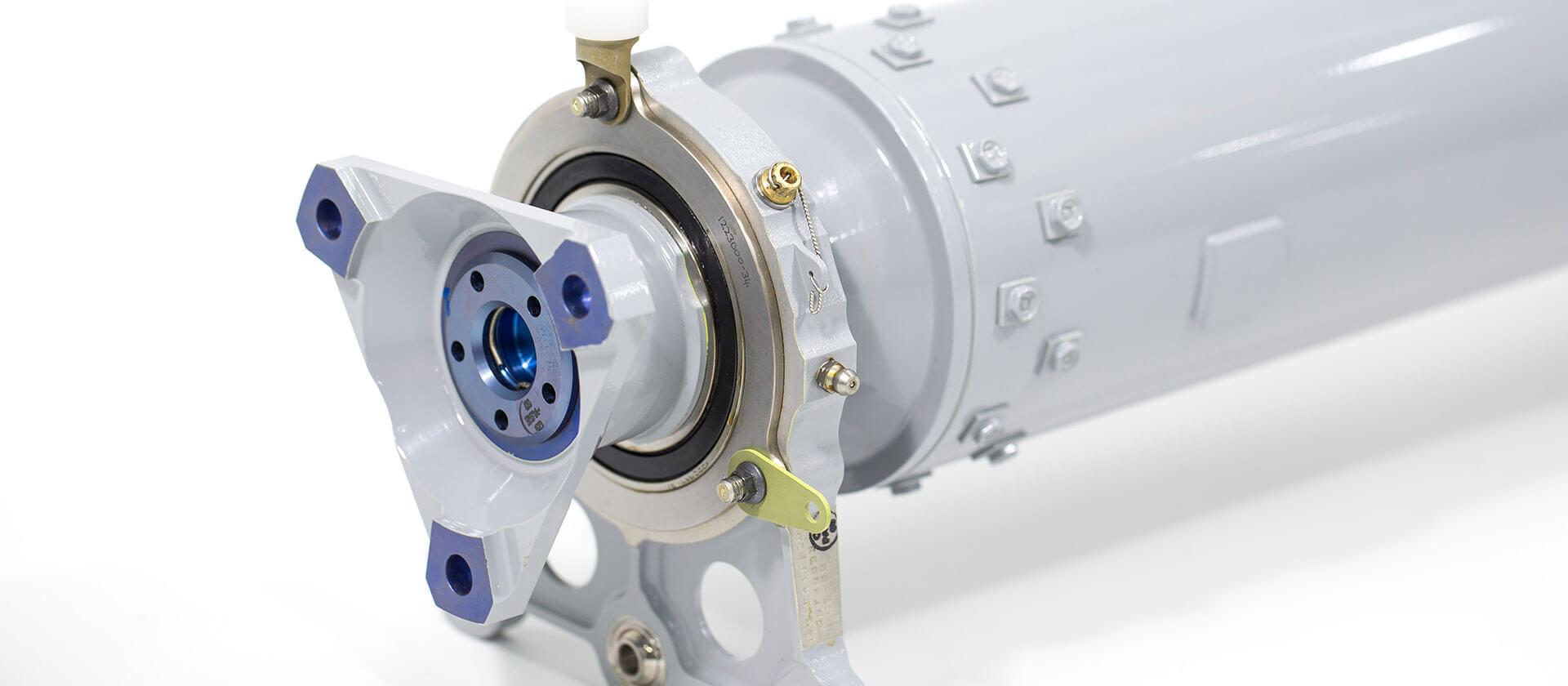

Drop forged parts by

A strong process

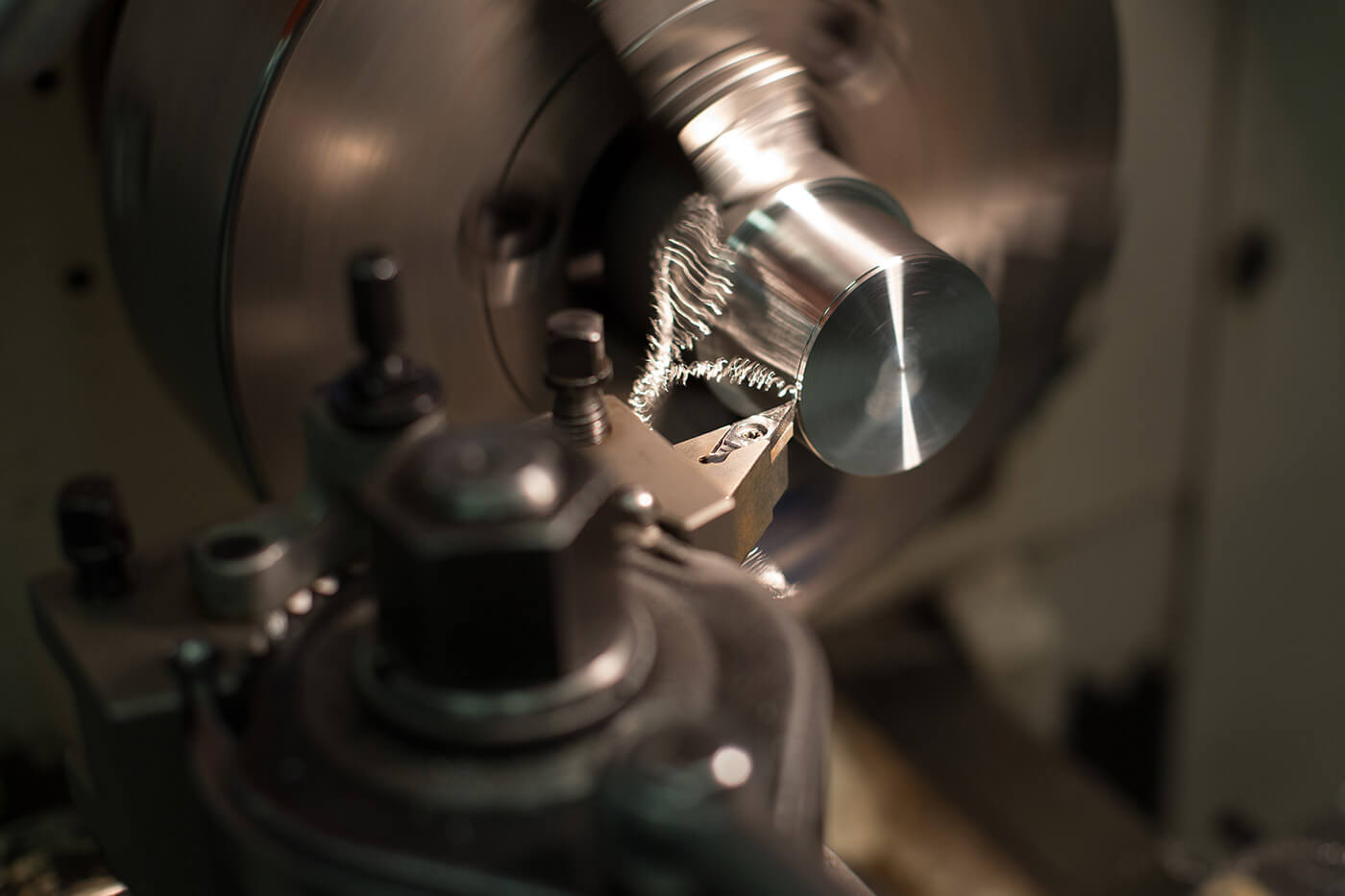

Design & Toolmaking

Machines are masters of reproduction, but people can innovate. The Knowledge gained from FEA simulations and years of experience is constantly incorporated into the technology of our forging tools. Thanks to the perfect interaction of state-of-the-art machine tools and experienced employees, tools are manufactured in-house, from semi-finished to ready-to-install.

Materials Management and Cutting

Several thousand tons of steel and aluminum are processed at our locations in Köflach and Kapfenberg per year. 7.5 m long bar steel bundles are unloaded by crane and stored in our fully automatic cassette storage facility with a capacity of 10,000 tons. Steel bar shears and fully magnetic saws enable the bar material to be cut to the section lengths required for forging in a matter of seconds.

Forging

Approximately 12 million drop forged steel parts are produced per year on 9 forging presses, with pressing forces between 1,000 – 1,800 tons. Our aluminium forging presses with pressing forces between 1,000 – 3,500 tons allow us to produce more than half a million drop forged parts per year. These parts involve hundreds of different geometric shapes, with tight tolerances and precisely defined mechanical properties, as well as ready-to-install visible components. Mainly responsible for our quality at the highest level is the harmonious interaction of our employees, forging presses and tools.

Heat Treatment

In order to achieve and maintain the required mechanical properties in a process-safe manner, optimised inhouse heat treatment tailored to each forged part is indispensable. Individual part hardening, directly through the forging heat, can minimise differences in strength or microstructure. With the help of our fully-automated isothermal annealing furnace we are able to anneal up to 4 tons of forged steel parts per hour. Our aluminum heat treatment consists of 4 furnaces for solution annealing, a quenching device and 2 furnaces for artificial ageing. All of our furnaces fulfil the requirements of CQI-9 respectively AMS2750 standards.

Quality

Our state-of-the-art quality assurance and measurement technology enable us to carry out economical and high-quality (100%) inspections of our forged parts. The quality of these tests, and the control loops derived from them, ensure our continuous, daily-practiced improvement process. To fulfil the high quality standards of our automotive and aerospace customers all of our aluminium parts run through a fully-automated pre-cleaning and pickling process followed by a liquid penetrant inspection. Additional to that we are able to apply surface finishing technologies such as sandblasting or vibratory grinding.

Maintenance

Maintenance, optimisation and ongoing digitization of our systems and plants are carried out exclusively by qualified Krenhof employees. To ensure that young workers in the future also follow our motto “A bit better every day”, we focus on excellence in our apprenticeship training. Apprenticeship at Krenhof

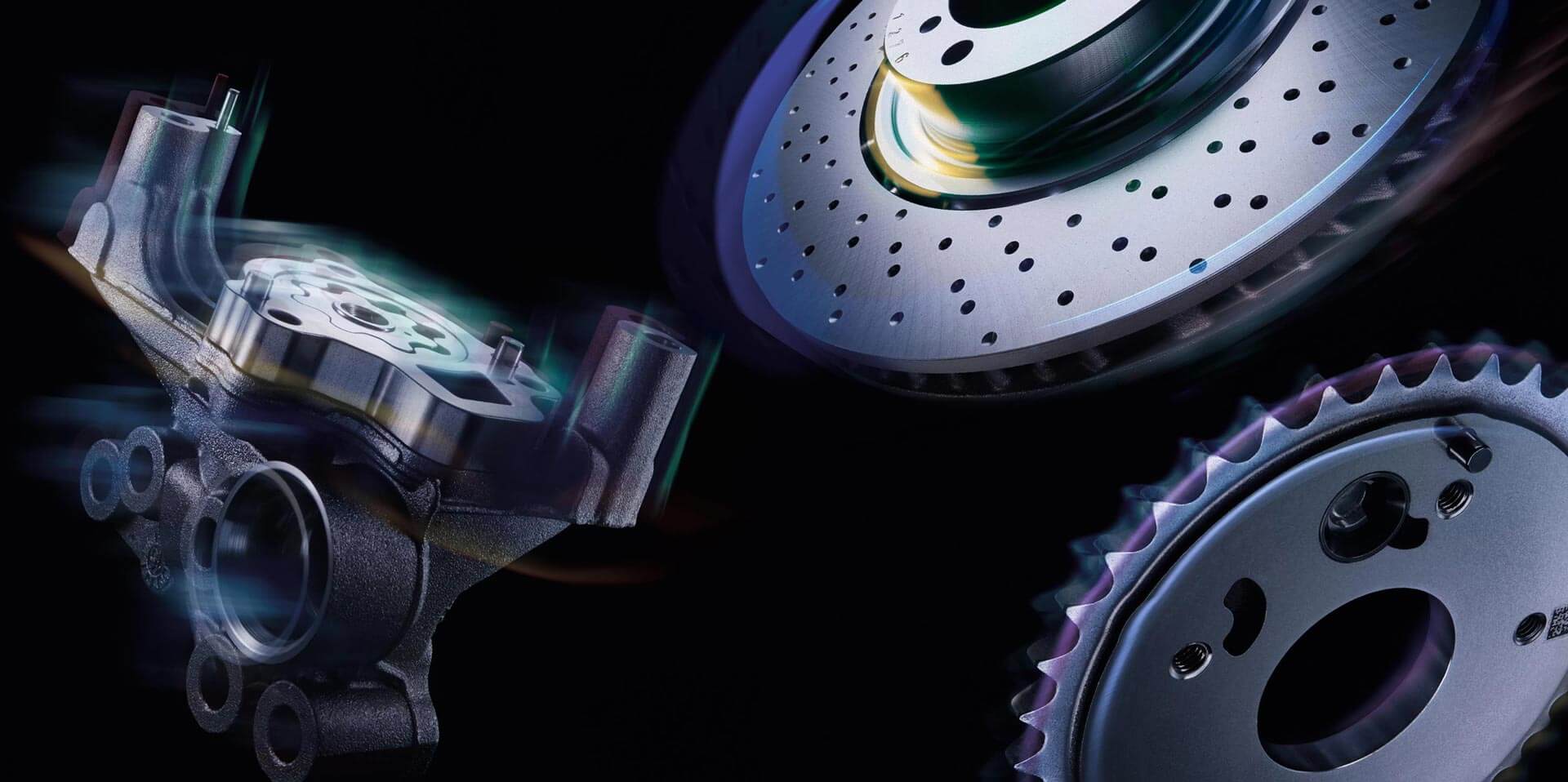

Precision at the highest level

With the help of a high level of digitalisation and sophisticated processes in forging, design, toolmaking, heat treatment, materials management, cutting and quality we offer our customers homogeneous parts, particularly in terms of geometry and microstructure. This allows customers to optimise their processes to a greater extent and thus generate further advantages. Krenhof has been established as a series supplier for decades in almost all well-known car brands, in trucks and motorbikes, agricultural machinery and the construction industry.

Also in the future, our customers and we will continue to be “A bit better every day”.