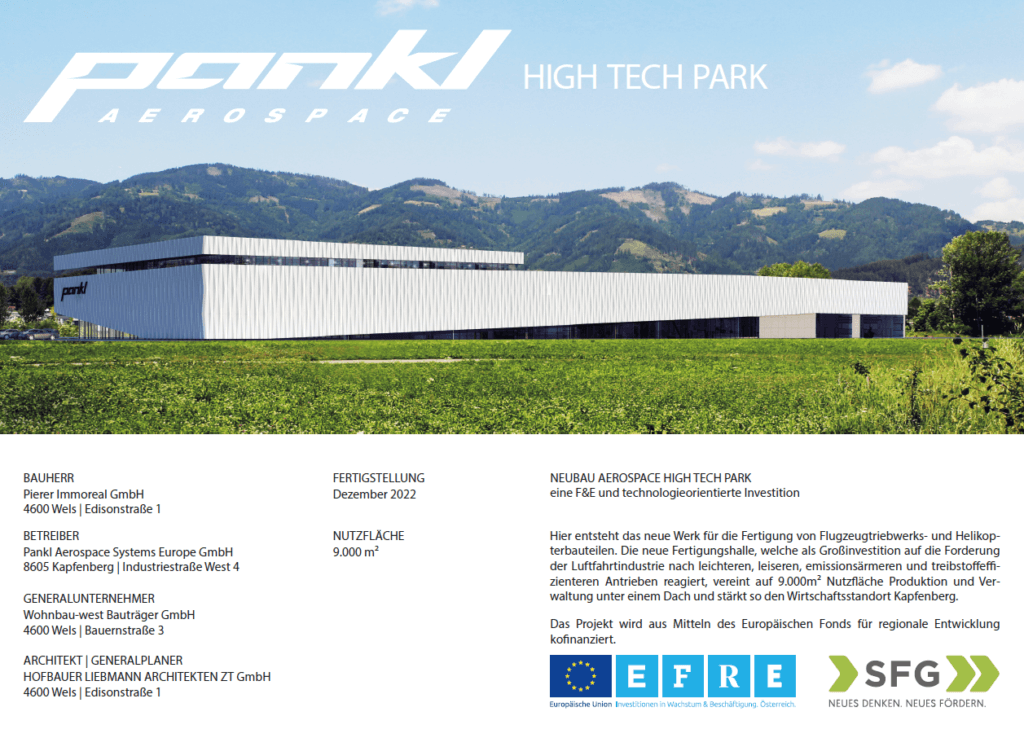

Innovative technological concepts will result in massive changes in aviation over the coming years.

Pankl Aerospace is already setting new standards when it comes to developing and manufacturing complex, flight safety engine systems and components.

Products & Core Competencies

01.

Perfection at

the highest level

Pankl Aerospace is among the top international suppliers of highly reliable, lightweight engine components and systems for the aerospace industry. Every single product is developed precisely to fulfill individual customer requirements. The result: tailor-made solutions that are optimised to exceed quality, functionality and safety. Practical experience in the aerospace sector that spans several decades, technological expertise and a global market presence with sites in Kapfenberg, Austria and Cerritos, California make Pankl Aerospace a reliable partner who takes tried-and-tested solutions further and optimises them in the process. The entire team aims to exceed customer expectations and requirements, and further strengthening trust by consistently proving our technical skills, competence and cooperation.

02.

Quality at

the highest level

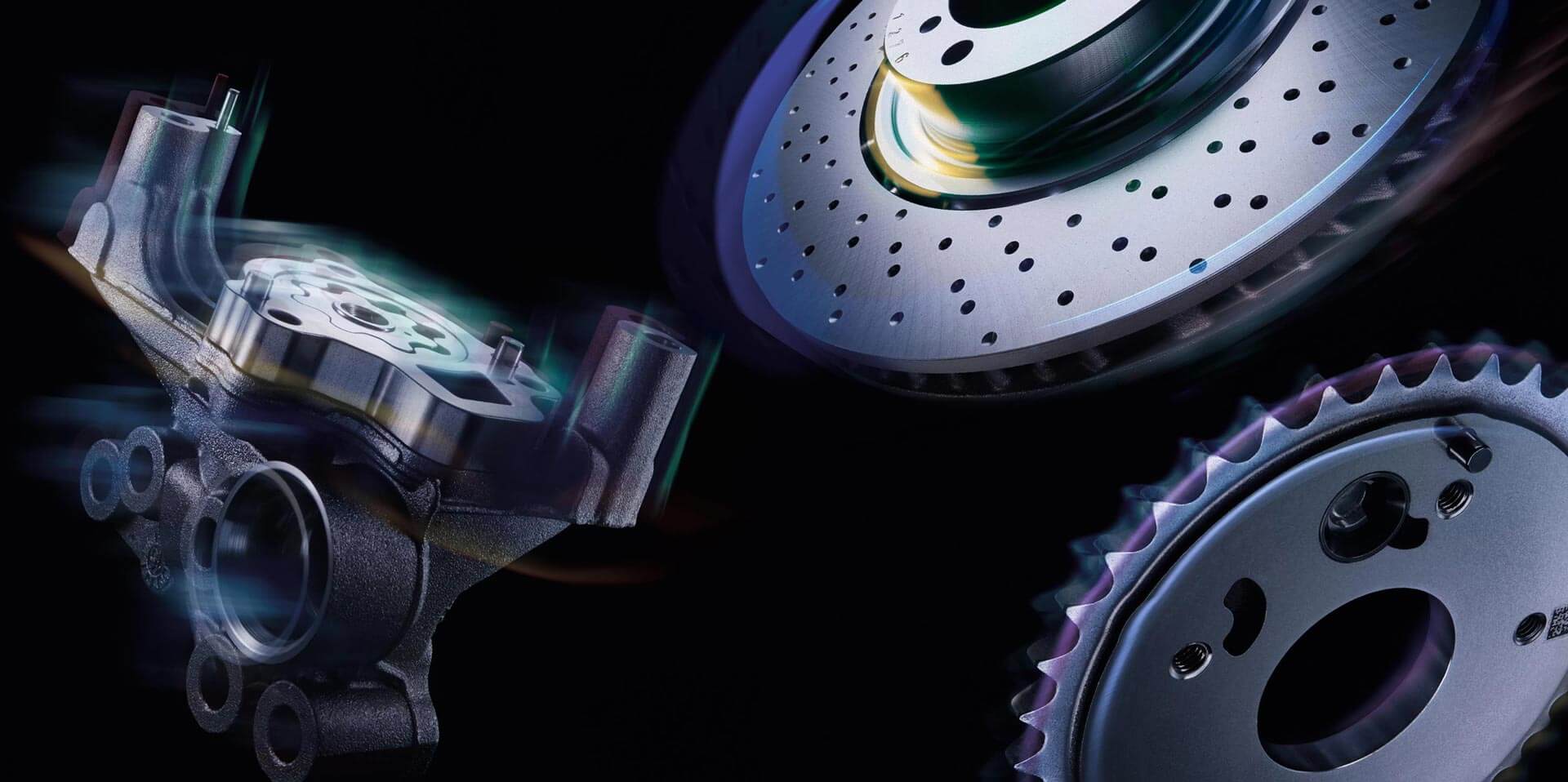

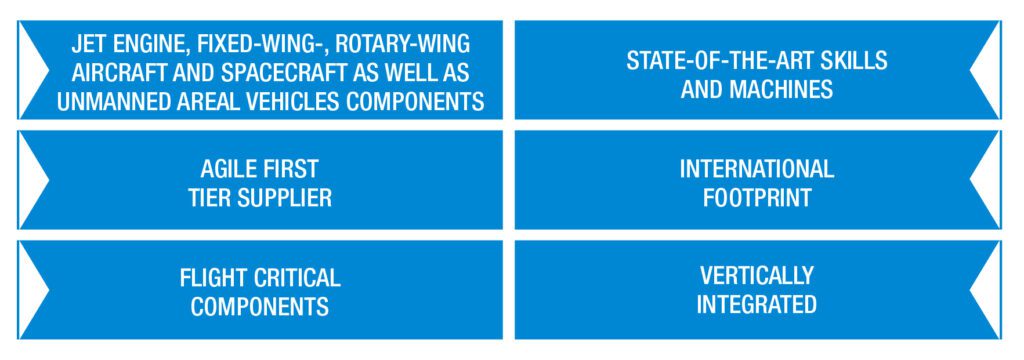

The Pankl Aerospace product portfolio is as varied as the wishes of our customers. The portfolio includes lightweight engine components and systems, rotor shafts, tubes for air refuelling systems and landing gear components for more than 60 different Jet Engine, Fixed-Wing-, Rotary-Wing Aircraft and Spacecraft as well as Unmanned Areal Vehicles, which comply with the stringent requirements of Federal Aviation Administration (FAA), and the European Aviation

Safety Agency (EASA). In addition, Pankl Aerospace is the flight safety parts supplier of choice for many OEMs, among them several market leaders in the aerospace industry.

HIGHEST SAFETY STANDARDS AND PRECISION

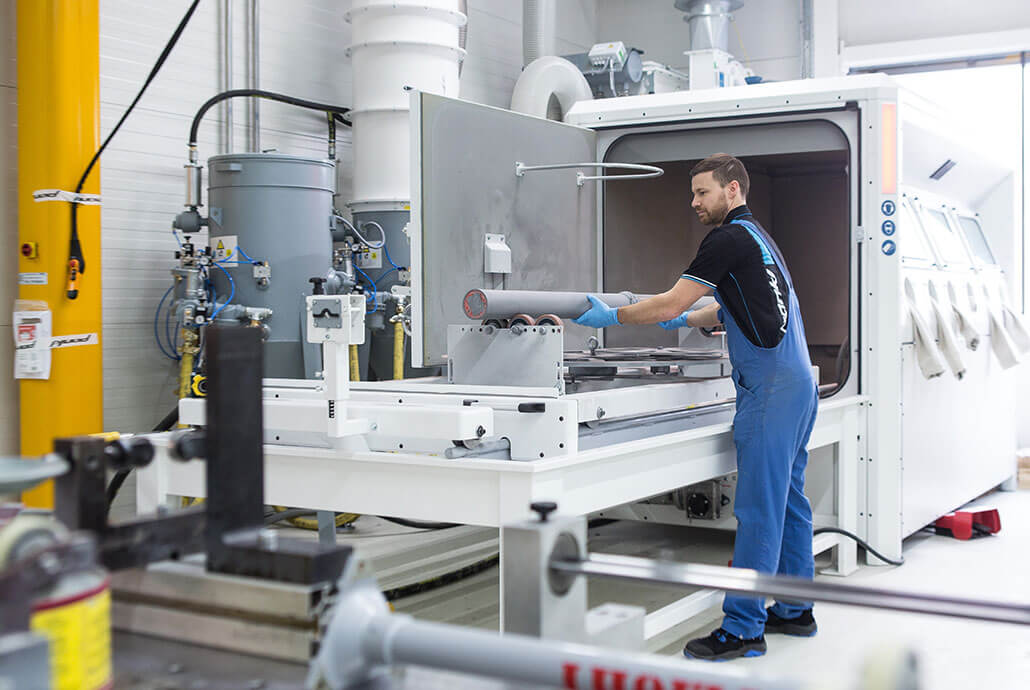

As a tier one supplier for the aerospace industry, Pankl Aerospace provides customised services for dynamic engine components: from design and development to assembly, manufacturing, material testing using the in-house laboratory, performance, stress and fatigue analyses, complete safety and reliability assessments, all the way to efficient prototype testing, qualification and certification.

All relevant processes, components and systems are approved by customers and certifying bodies (EN 9100, ISO 14001) as well as by the European Aviation Safety Agency and Austro Control (Part 21G POA and Part 21J DOA). Further to this, the special processes painting and the non-destructive testing methods eddy current testing, magnetic particle testing and fluorescent penetrant testing, performed at Pankl Aerospace Systems Europe within the scope of manufacturing, are accredited by the industry standard Nadcap (AC7108, AC7114).

Key elements include our sophisticated quality management system and state-of-the-art, high-tech processes for developing, manufacturing and assembling complex powertrains and other components for the challenging aerospace market.

EFFICIENCY AND ENVIRONMENTAL AWARENESS

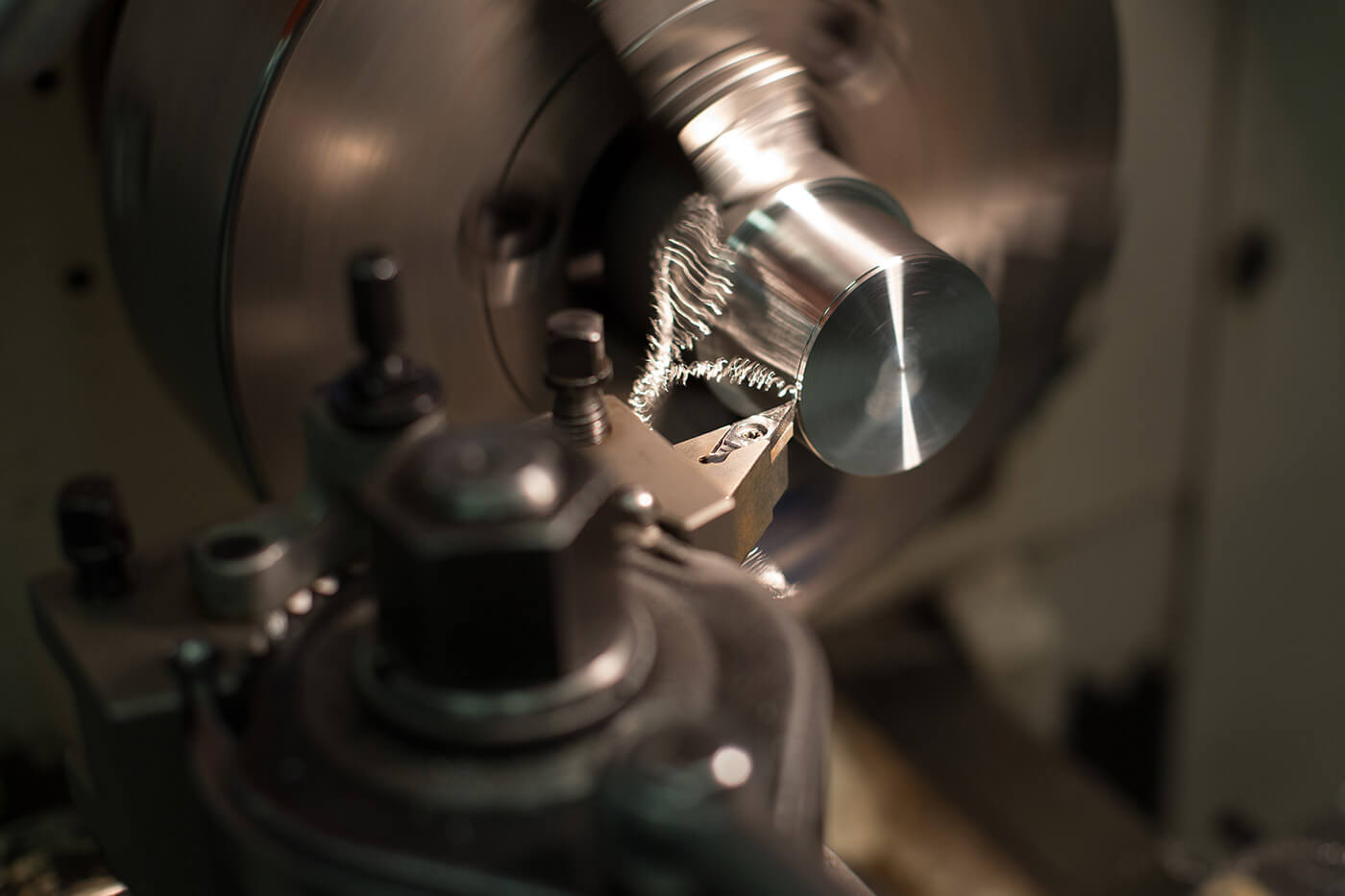

Today, the aerospace industry requires lighter, quieter engines with reduced emissions and higher fuel efficiency. Pankl Aerospace has paved the way for the manufacturing of innovative, safety-critical structural components that are set to make flying more efficient and environmentally compatible in future. Our state-of-the-art machines with innovative turning and milling applications are optimised and improved on an ongoing basis. They are positioned to overcome the technological challenge of processing alloys for the aerospace industry that are notoriously difficult to machine.

Additionally, we use the latest technologies for assembly, bonding, as well as high-precision balancing of rotative components.

All these synergetic effects create a wide range of services with short development times, efficient logistics, and supply chains ensuring optimal results from a single source.

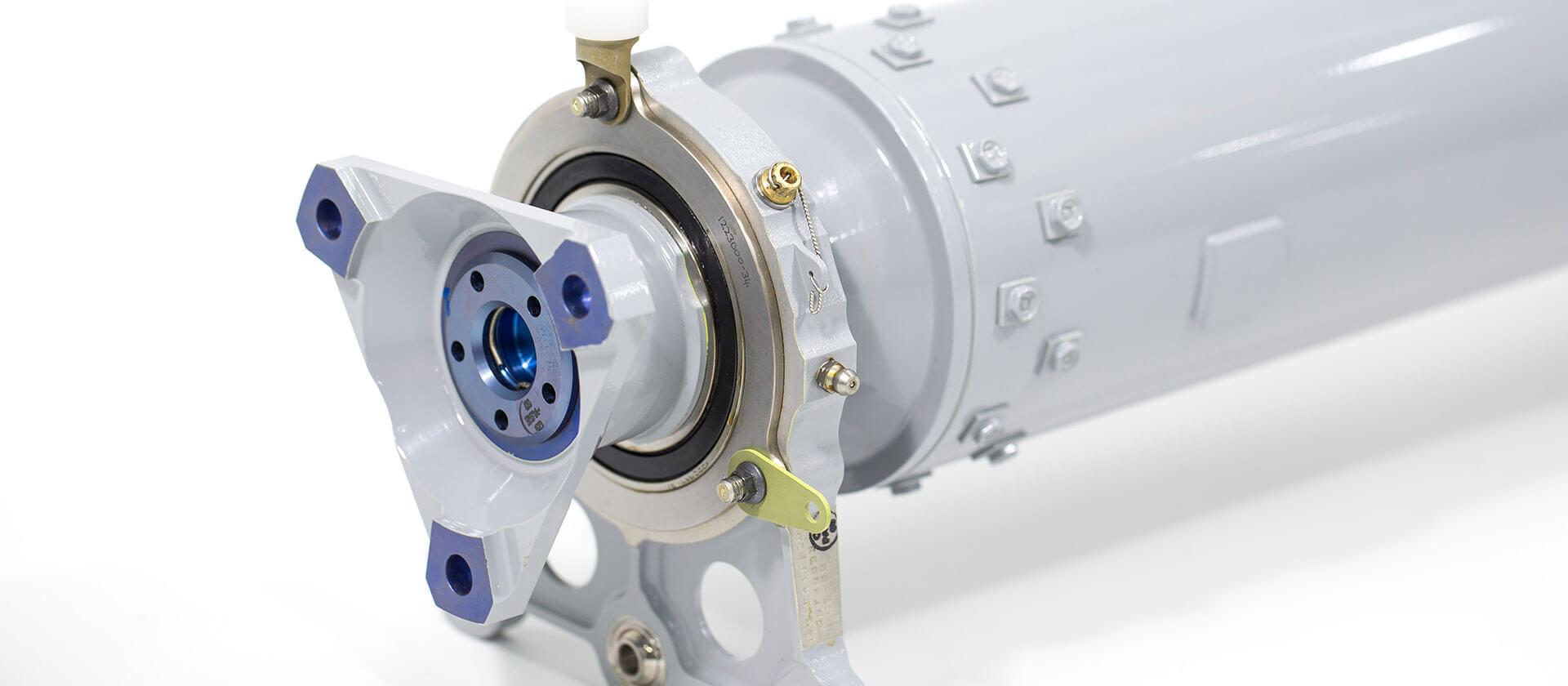

DEVELOPMENT OF FLEXIBLE COUPLINGS

FOR HELICOPTER DRIVELINE APPLICATIONS

Couplings form an essential part for all tail rotor drive line systems for helicopters and UAVs. In order to expand Pankl Aerospace’s core competence in the production of tail rotor shafts to the production and development of complete tail rotor drive systems, it is necessary to develop and manufacture innovative couplings.

The Pankl Aerospace product segment already covers tail rotor shafts, damping elements and bearings for tail rotor systems.

The development of couplings would cover the last missing element of the complete tail rotor drive system. The aim of this project is therefore the development of an advanced coupling exactly for this application. By evaluating different types of couplings, manufacturing methods, materials and simulation models, a product is to be created which offers significant added value compared to the solutions currently available on the market.

The creation of sustainable technical knowledge in this context is inter alia ensured through cooperation with external scientific partners. This project is co-financed by the European Regional Development Fund.

PRODUCTS

In the aerospace division we develop products from the areas of forged parts and aerospace.