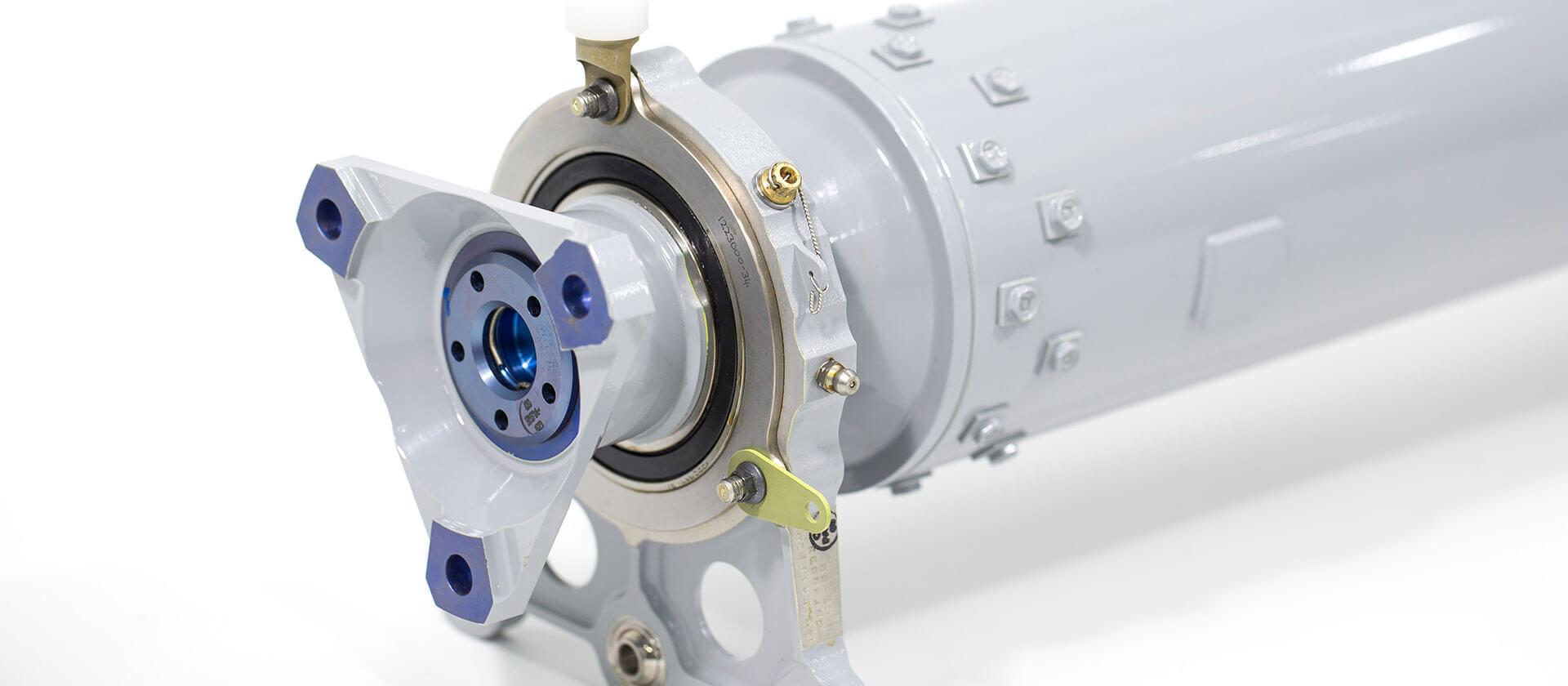

Pankl relies on the latest manufacturing and surface treatment equipment as well as on the outstanding expertise of its process engineers, making it possible to fulfil even the strictest quality and process requirements of customers throughout the process chain.

The ongoing development of manufacturing processes contributes towards continuous product improvement and guarantees new solutions for our partners on a regular basis.

Customers have a defined contact partner at their disposal from the start of a project, throughout the development process and all the way to the finished product; this contact person is in charge of the whole customer project and is supported by a team of experts. The result: direct, efficient project management for their benefit!

This is what Pankl Racing Systems works towards on a daily basis, in close cooperation with customers and experts all over the world.

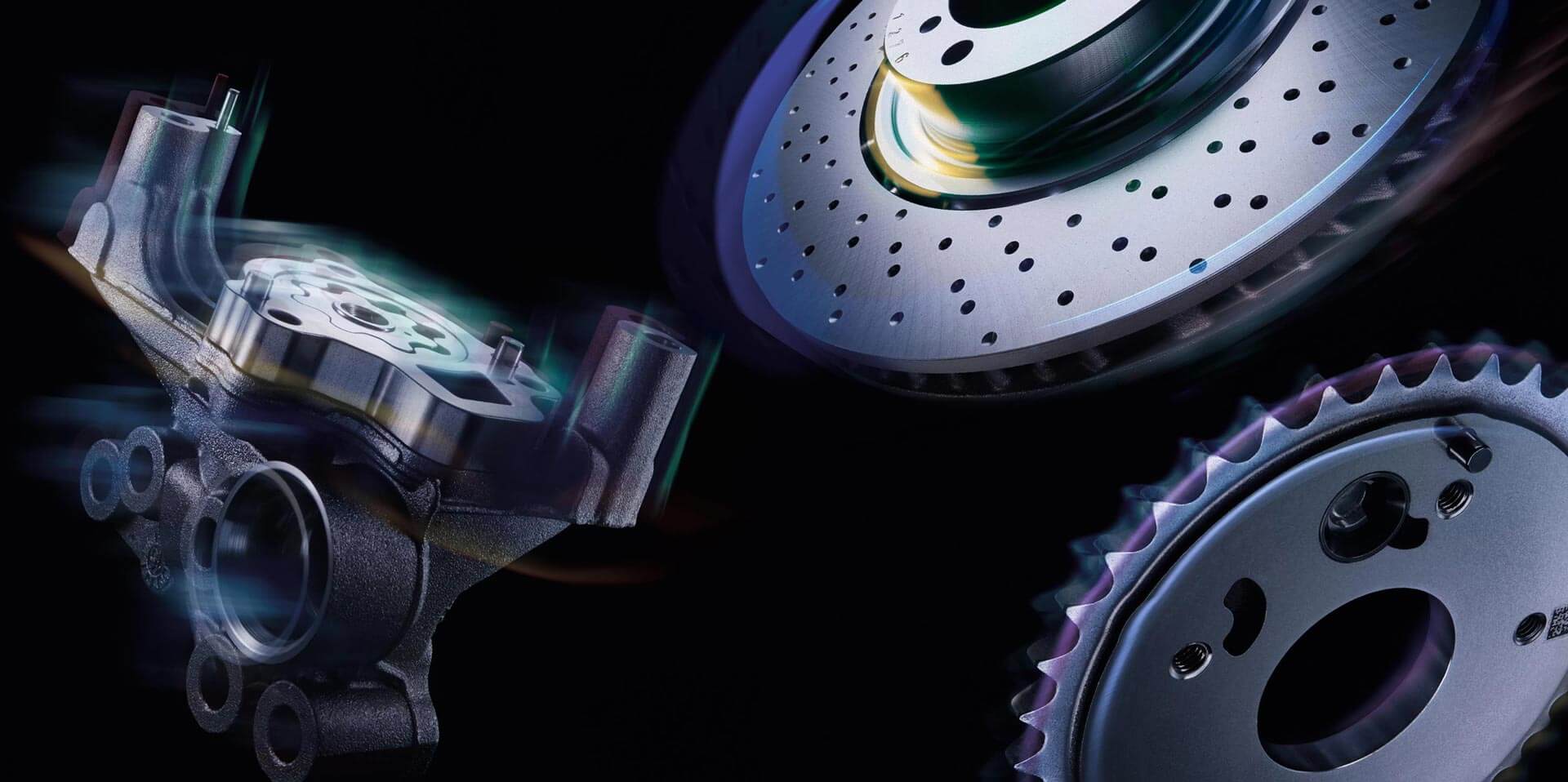

The mobility of the future is based on new developments and innovative technologies, in particular those using tomorrow’s materials. New ideas and solutions when it comes to material for engine and drivetrain technology also require completely new approaches that go far beyond the current standard.

TECHNOLOGICAL KNOW-HOW

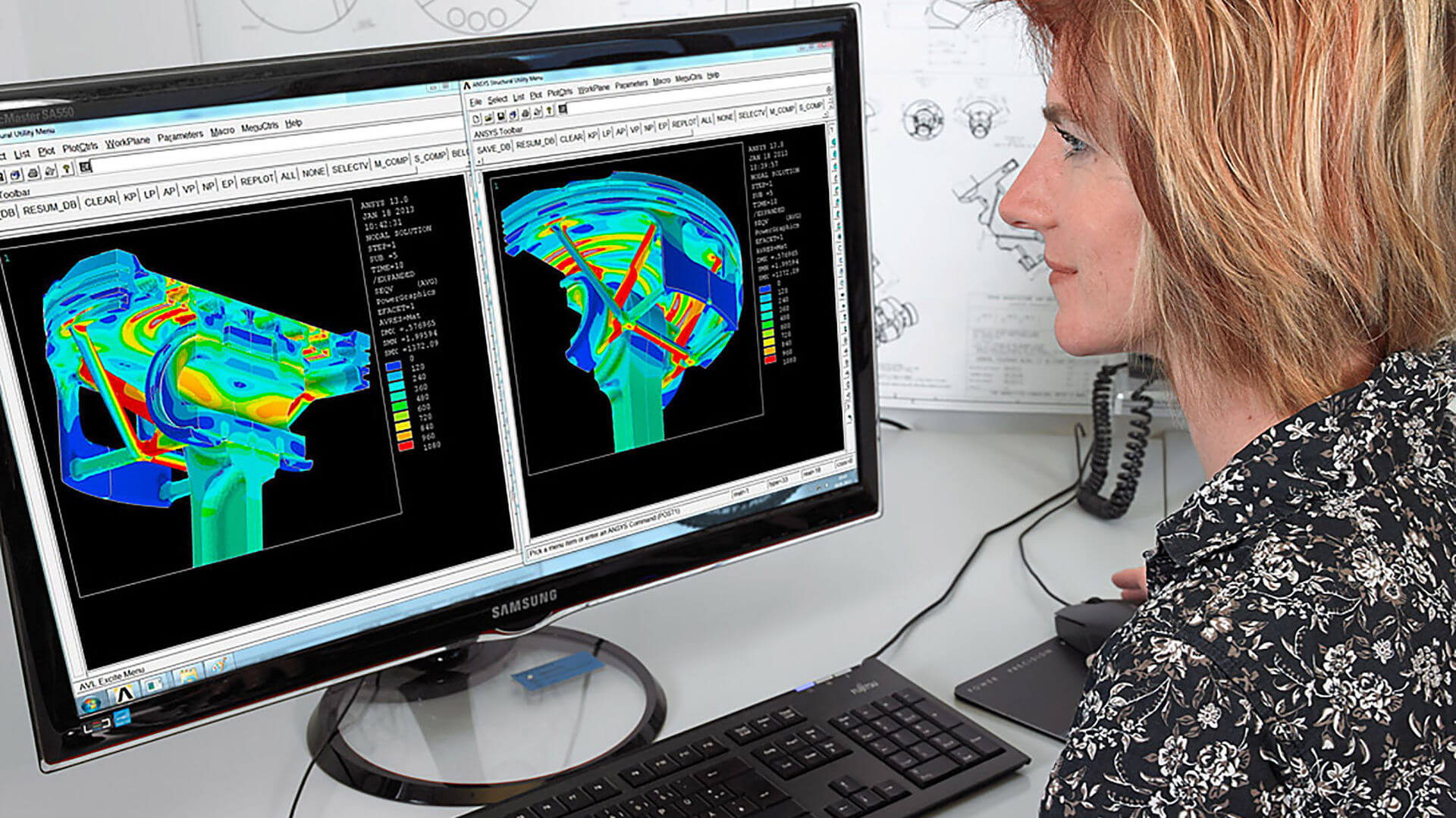

During the entire development phase of every single component, the Pankl design engineers are faced with the challenge of putting together highly different, sometimes even contradicting requirements to form a coherent concept. The ongoing dialogue between the design, testing and simulation departments and the regular exchange with customers are essential prerequisites for developing effective solutions that live up to customer-specific guidelines and comply with all applicable legal requirements.

HIGH RELIABILITY

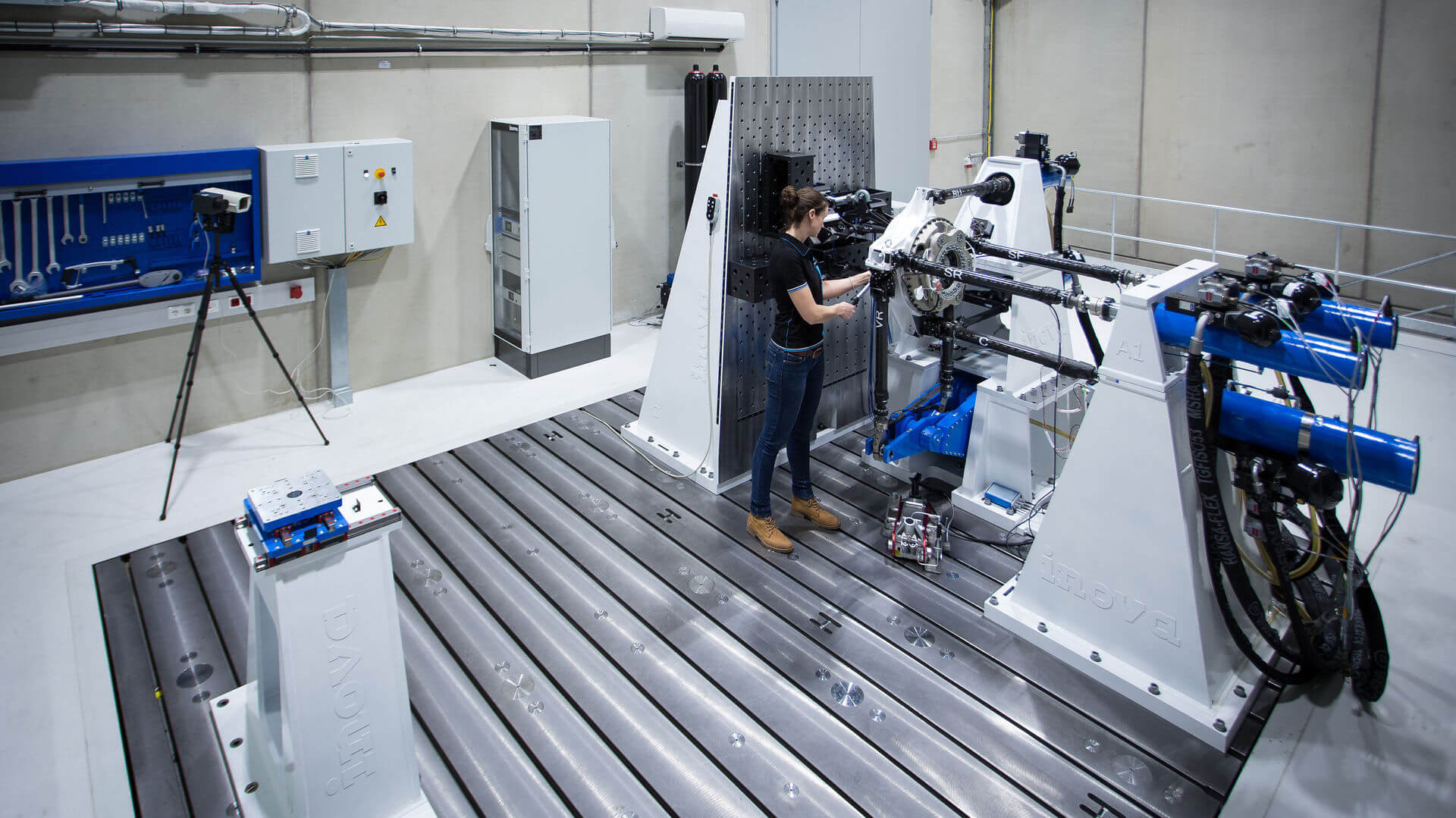

Engine and drivetrain concepts are currently undergoing a period of massive transformation. The goal is: best performance and the highest possible safety, combined with minimised fuel consumption and reduced emissions. These new, revolutionary requirements and increasingly complex systems require strict control and test mechanisms – and Pankl has the state-of-the-art test equipment available to fulfil these requirements.