The Pankl Additive Manufacturing Competence Center (PAMCC) constitutes so far the largest cooperation of technology enterprises in the fields of:

Powder Development

Process Technology

Application Engineering

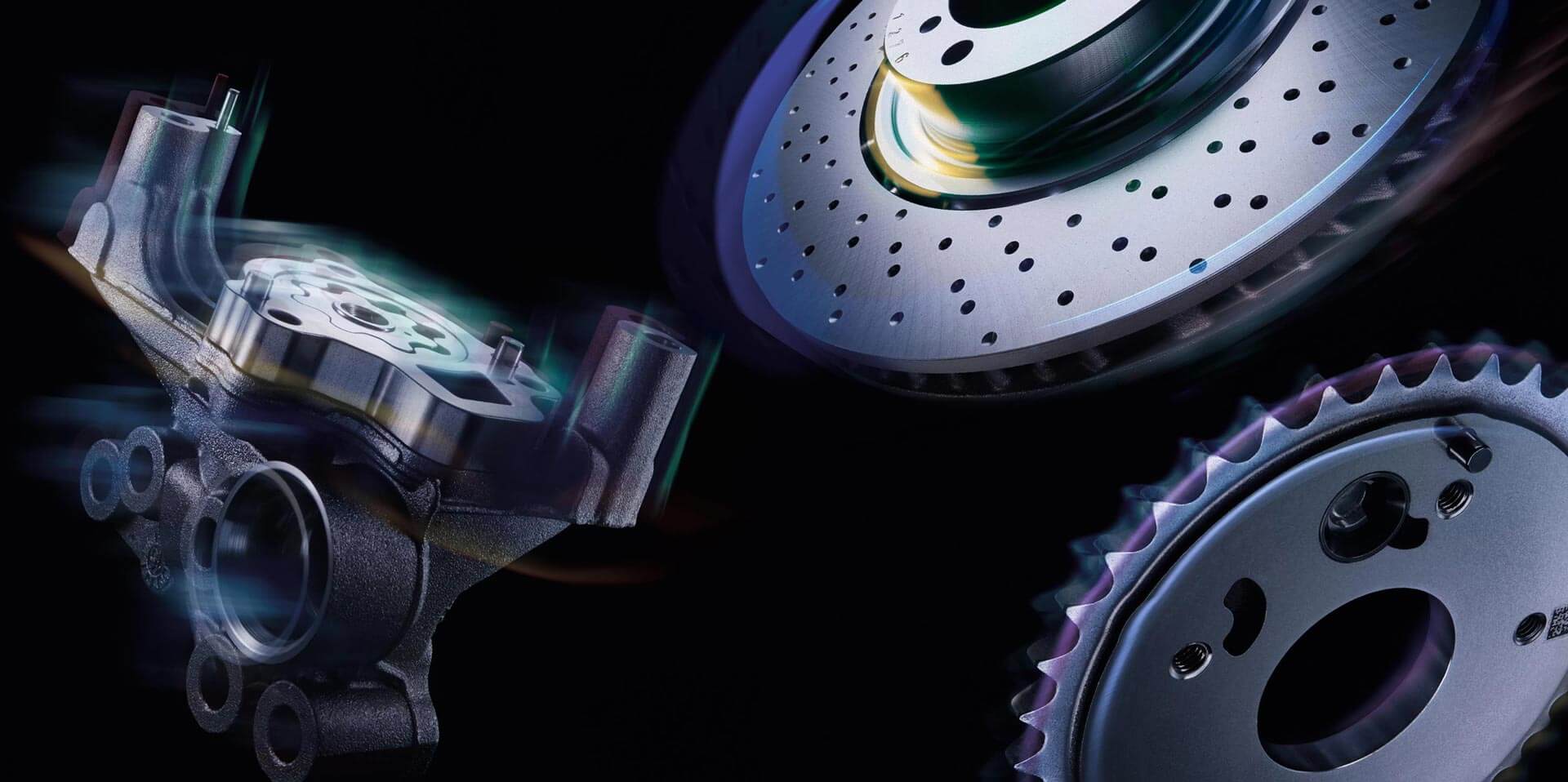

Together with globally known brands such as voestalpine Böhler Edelstahl, EOS and Quintus Technologies, Pankl Racing Systems has set up its competence centre with the goal of pushing the limits of AM further and to strengthen its position particularly in the automotive high-performance and aerospace fields.

The cooperation with voestalpine Böhler Edelstahl, a globally leading enterprise in the high-performance metal industry, makes it possible to embark on a joint, customised development process of innovative and optimised metal powders as ideal starting products for the printing process.

With EOS, we were able to gain the support of the pioneering provider of laser sintering machines. EOS not just brings many years of experience with regard to process technology, but also provides us with the latest generation of machines even before they are launched on the market.

crossing boundaries together

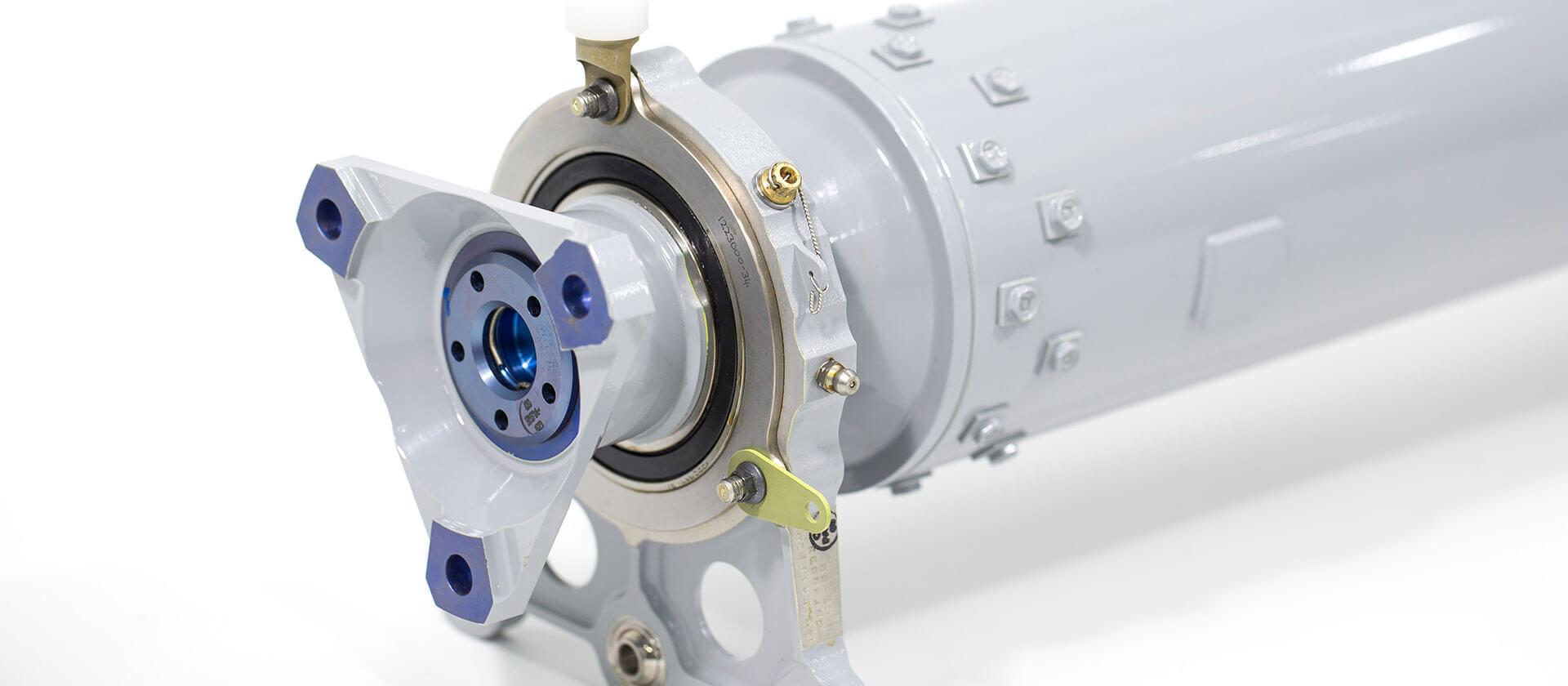

The right thermal after-treatment is the fundamental basis for the functionality of printed components. For this reason, we also installed an HIP-press (Hot Isostatic Press) by our partner and globally leading provider Quintus Technologies.

Our close cooperation with leading universities, in particular with the Leoben University of Mining and Metallurgy, aims at familiarising students with Additive Manufacturing, and focuses especially on showing them which new requirements and challenges it brings.

Unrivalled Quality

and Logistics

In combination with the wide-ranging development competence and the existing market access of Pankl Racing Systems, this cooperation is the ideal basis for the development of innovative products as well as tailor-made solutions for the racing and the aerospace industries and to support our customers as best we can when it comes to imple-menting Additive Manufacturing.

The fact that we have full control over the complete added-value chain helps us optimise quality and logistics on the one hand and drive and perfect development in all areas on the other, from powder production to process implemetation all the way to after-treatment.

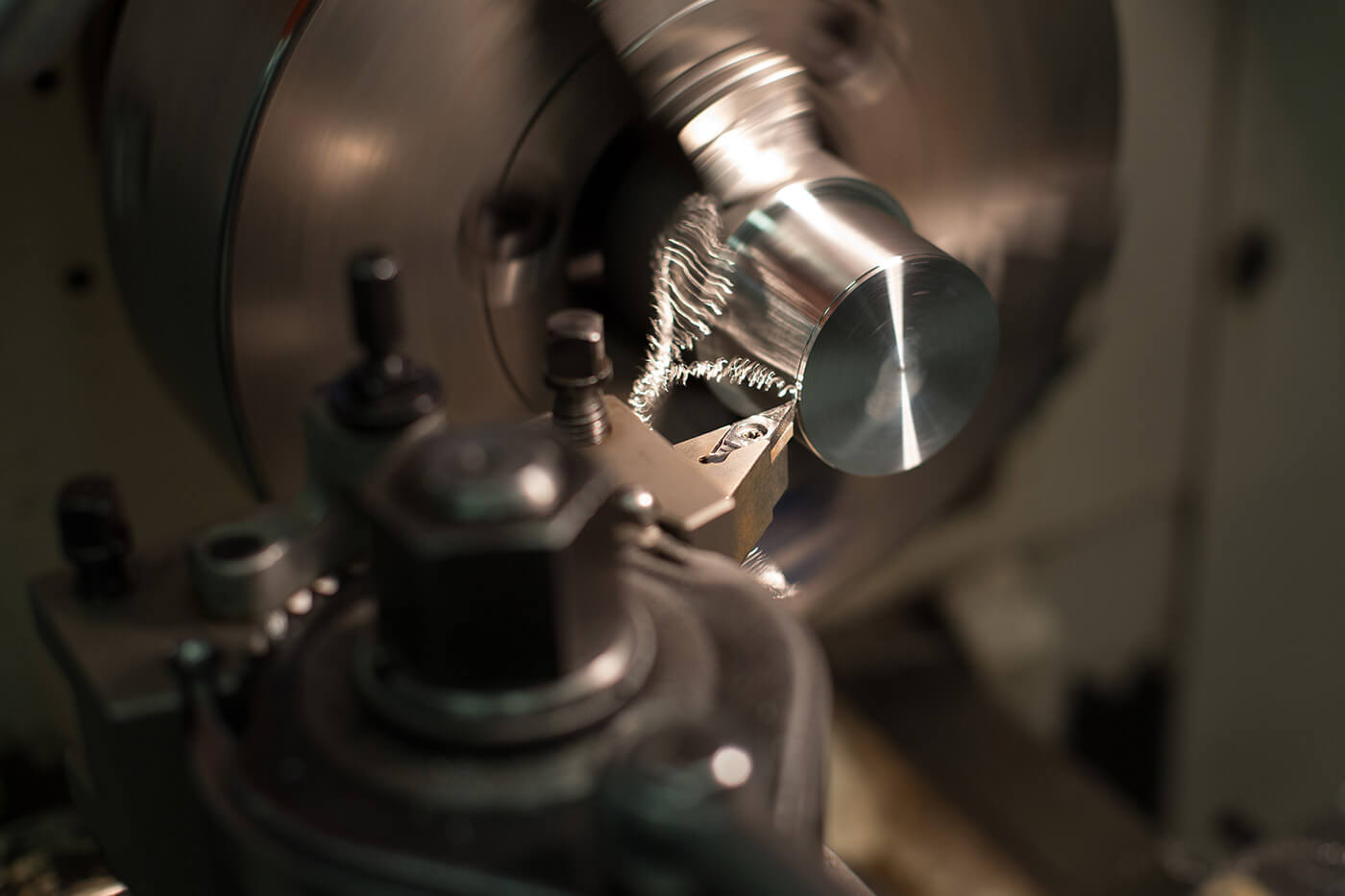

PROCESS TECHNOLOGY

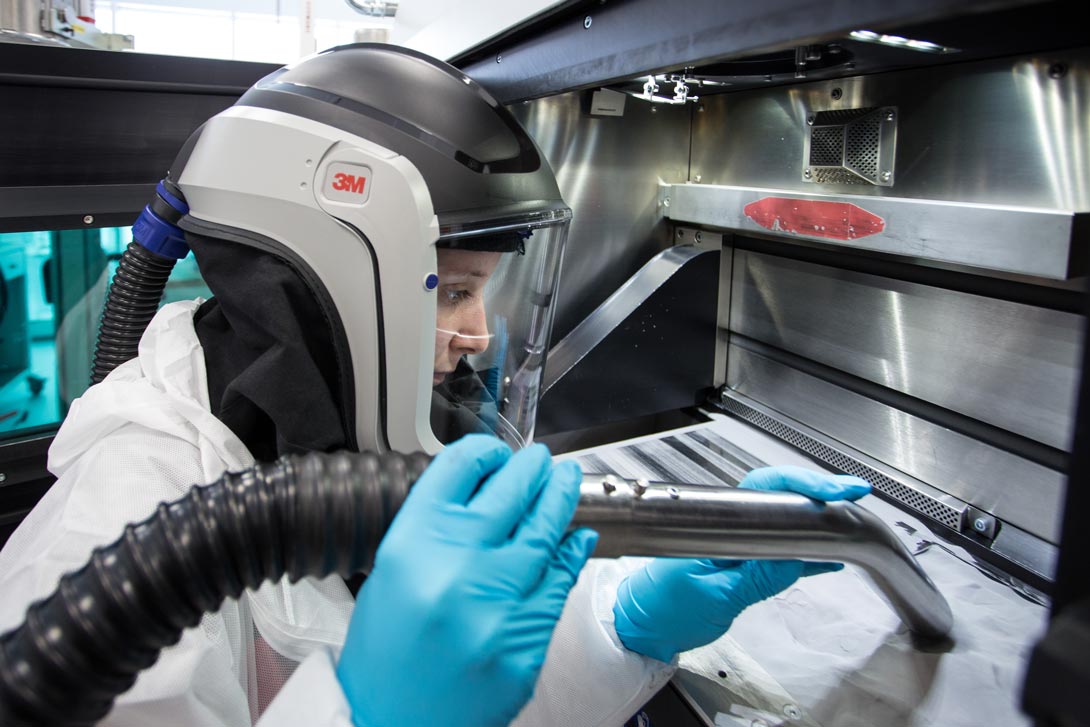

The entire process up to the finished product is handled by Pankl in-house and supervised by our team of AM specialists.

The process involves the development, selection and analysis of the most suitable powder. The design optimization of the component and the ideal positioning are followed by a key process for the later product.

After the successful printing process, various processes, such as surface treatment or heat treatment, improve the properties of the component.

Our Partners

In addition to the internal investigation opportunities at Pankl Racing Systems, the cooperation with voestalpine Böhler Edelstahl – a globally leading enterprise in tool steels, high-speed steels and special materials – makes it possible to access the latest atomisation- and lab facilities, as well as to embark on a joint, customised development process for innovative and optimised metal powders as ideal starting products for the printing process.

Read more

With EOS, we were able to secure the support of a global leader in technology and quality for high-end solutions for the Additive Manufac-turing sector, a pioneer in the production of and market leader in laser sintering machines with long-year experience in process technology.

Read more

As the correct thermal after-treatment is the fundamental basis for the functionality of AM components, we decided to invest in a new vacuum heat-treatment system as well as a dedicated HIP (Hot Isostatic Press), which consolidates components using high pressure and temperature, thereby increasing their lifespan significantly. In this context, we were lucky to get Quintus Technologies on board, a technology leader in high-pressure technology and a valuable strategic third partner for our competence centre. The first HIP machine worldwide that has been specially adapted for AM applications was installed by Quintus Technologies in the Pankl Additive Manufacturing Competence Center.

Read more