Kapfenberg

Pankl Racing Systems AG

Pankl Racing Systems AG develops, manufactures and distributes mechanical systems in the high-tech field for dynamic components in the global niche markets motor racing, luxury / high performance cars and aerospace.

The overall strategic goal of the Pankl Group is to be the leading supplier and development partner of engine and drive systems. This position as a systems supplier, offering services ranging from development and calculation, production and assembly to testing and maintenance of high-performance components, sets us apart from our competitors. Pankl Racing Systems AG employs over 1800 people worldwide.

Contact:

Phone: +43 (0) 3862 33 999-0 | Fax: +43 (0) 3862 33 999-981

[email protected]

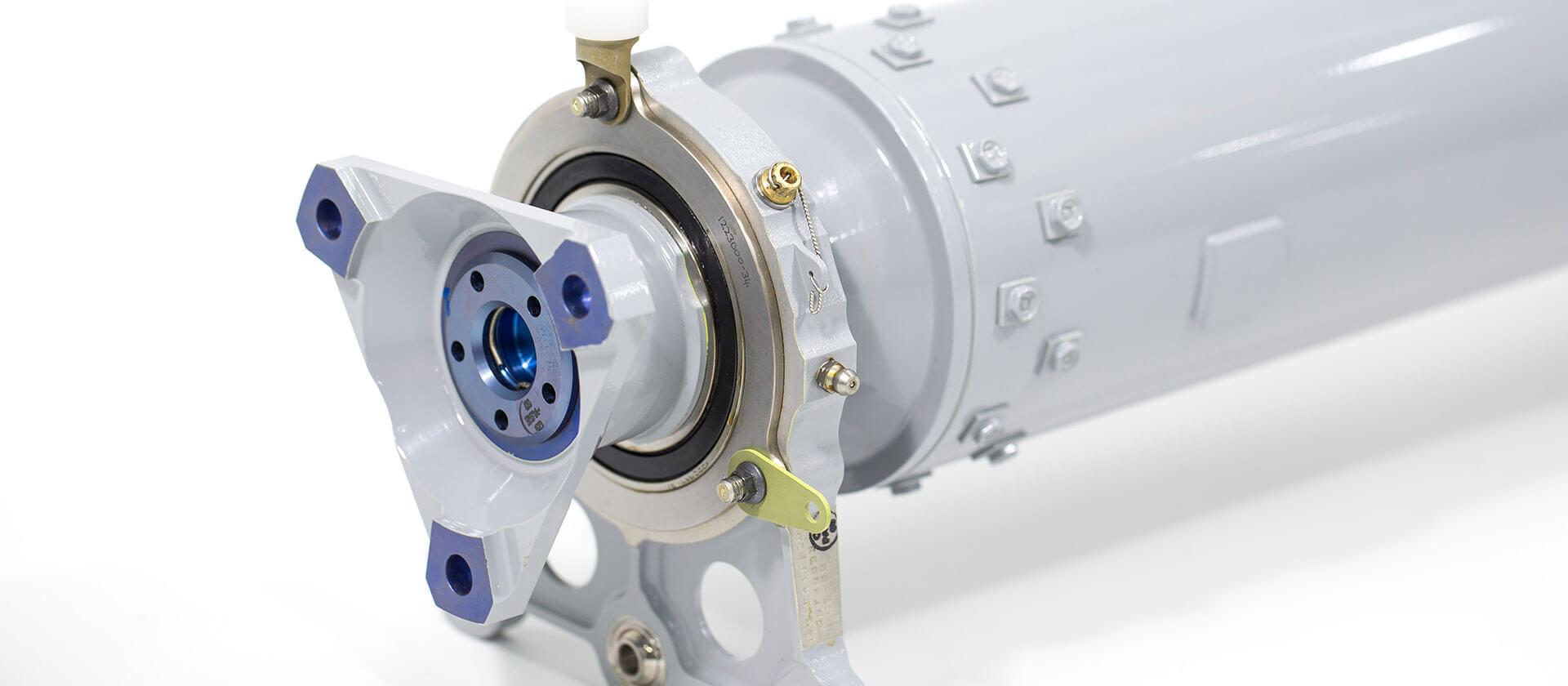

Pankl Racing Systems AG, Drivetrain & Suspension Systems

| Division | Racing |

| Technology | Machining, Additive, Heat Treatment |

| Products | Drivetrain/Gearbox |

| Certifications | ISO 9001 ISO 14001 VDA 6.1 |

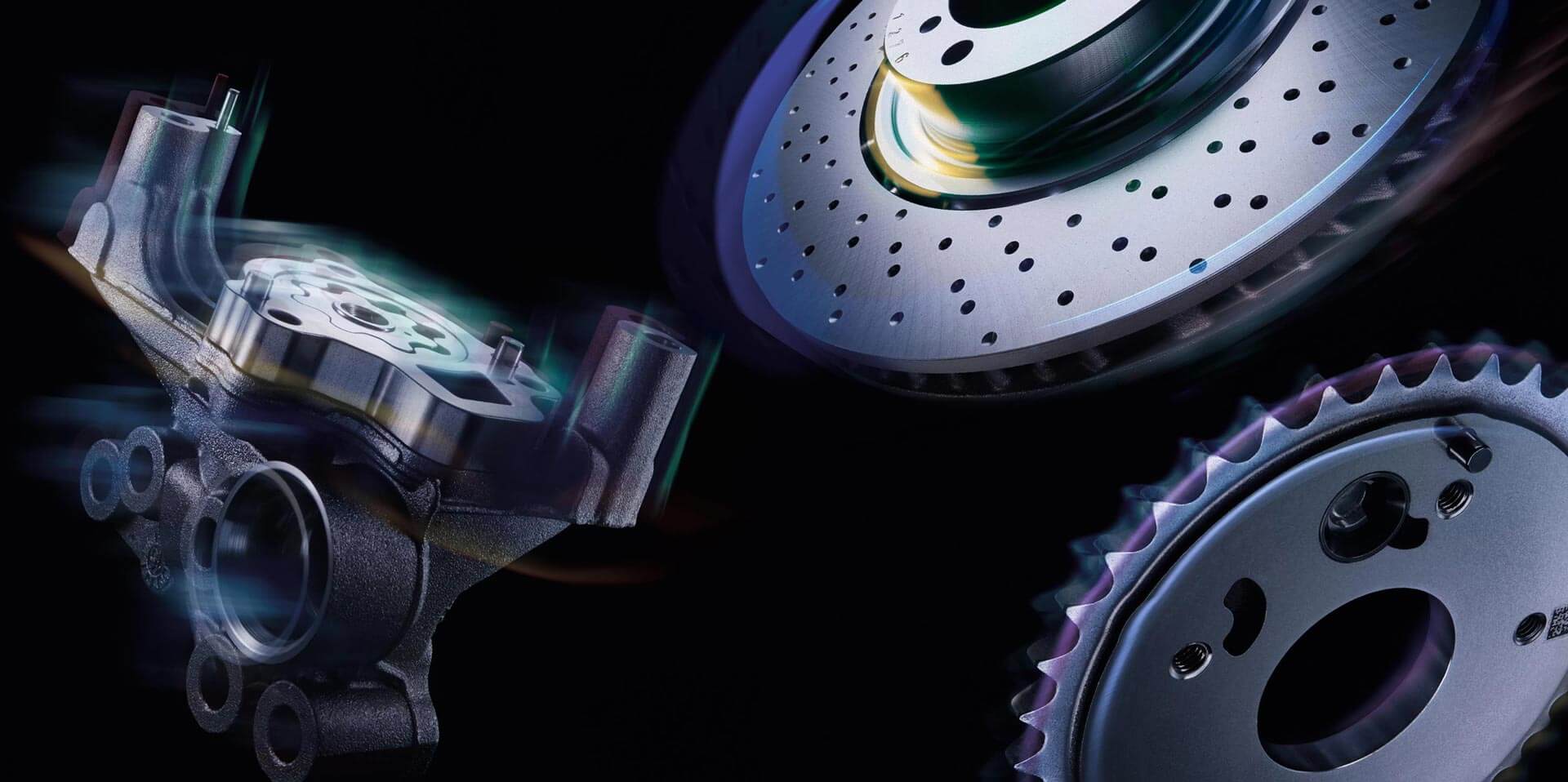

Pankl Drivetrain & Suspension Systems is a major global player in the challenging market of motorsports and exclusive high performance vehicles. Our portfolio consists of assemblies and individual components; beyond that, we offer our customers complete solutions such as drivetrain or suspension systems.

Furthermore, suspension and drivetrain components can be tested and validated on our high-tech testrigs.

Pankl Drivetrain & Suspension Systems key products are: Driveshaft assemblies, tripod and CV Joints, integrated (one piece) or conventional splined connection driveshaft components, wheel hubs with and without integral tracks, uprights (forged and machined), gears, gearbox output housings, prop shafts (steel, aluminum, titanium and carbon fibre), wishbones, brackets and complex machined components.

Contact:

Phone: +43 (0) 3862 33 999-0 | Fax: +43 (0) 3862 33 999-719

[email protected]

Pankl Aerospace Systems Europe GmbH

| Division | Aerospace |

| Technology | Machining, Heat Treatment |

| Products | Aerospace |

| Certifications | ISO 9001 ISO 14001 Part 21J EN 9100 Part 21G Nadcap NDT Nadcap CP – High Tech Park 1 Nadcap CP – Industriestrasse West 4 Nadcap HT Nadcap SE |

Pankl Aerospace with operations in the US and Europe is serving the global aerospace market as a Tier One Supplier for transmission components, engine shafts, refuelling tubes and landing gear parts for fixed and rotary wing aircraft. They are also involved in specific aircraft design projects, co-operating with prime manufacturers for design, test and qualification.

A FAA approved dynamic test rig enables rapid prototyping offering our customers short development times including documentation for qualification and airworthiness certification.

Contact:

Phone: +43 (0) 3862 33 999-0 | Fax: +43 (0) 3862 33 999-860

[email protected]

Krenhof GmbH

| Division | Automotive, Industrial Applications, Truck & Off-Highway, Two Wheeler |

| Technology | Heat Treatment, Forging |

| Products | Forged Parts |

| Certifications | ISO 9001 EN 9100 ISO 14001 |

Krenhof – A member of the Pankl Group manufactures precision forged components for the Industries: Automotive, Industrial Applications, Truck & Off-Highway and Two Wheeler. Our in-house tool making allows us to offer competitive lead times for prototypes. Non-destructive material tests can be carried out in house full automatically, on many different materials such as Steel and Aluminum according to the very latest international standards.

Components from Krenhof are applied in areas, where high demands on production expertise, quality, reliability, materials and design are an absolute must.

Contact:

Phone: +43 (0) 3862 33 999-0 | Fax: +43 (0) 3862 33 999-910

[email protected]

Pankl Racing Systems AG, High Performance Systems

| Division | High Performance |

| Technology | Machining, Additive, Heat Treatment |

| Products | Drivetrain/Gearbox |

| Certifications | ISO 9001 ISO 14001 EN 9100 PAMTEC ISO 9001 PAMTEC ISO 14001 PAMTEC EN 9100 PHTC EN 9100 PHTC ISO 9001 |

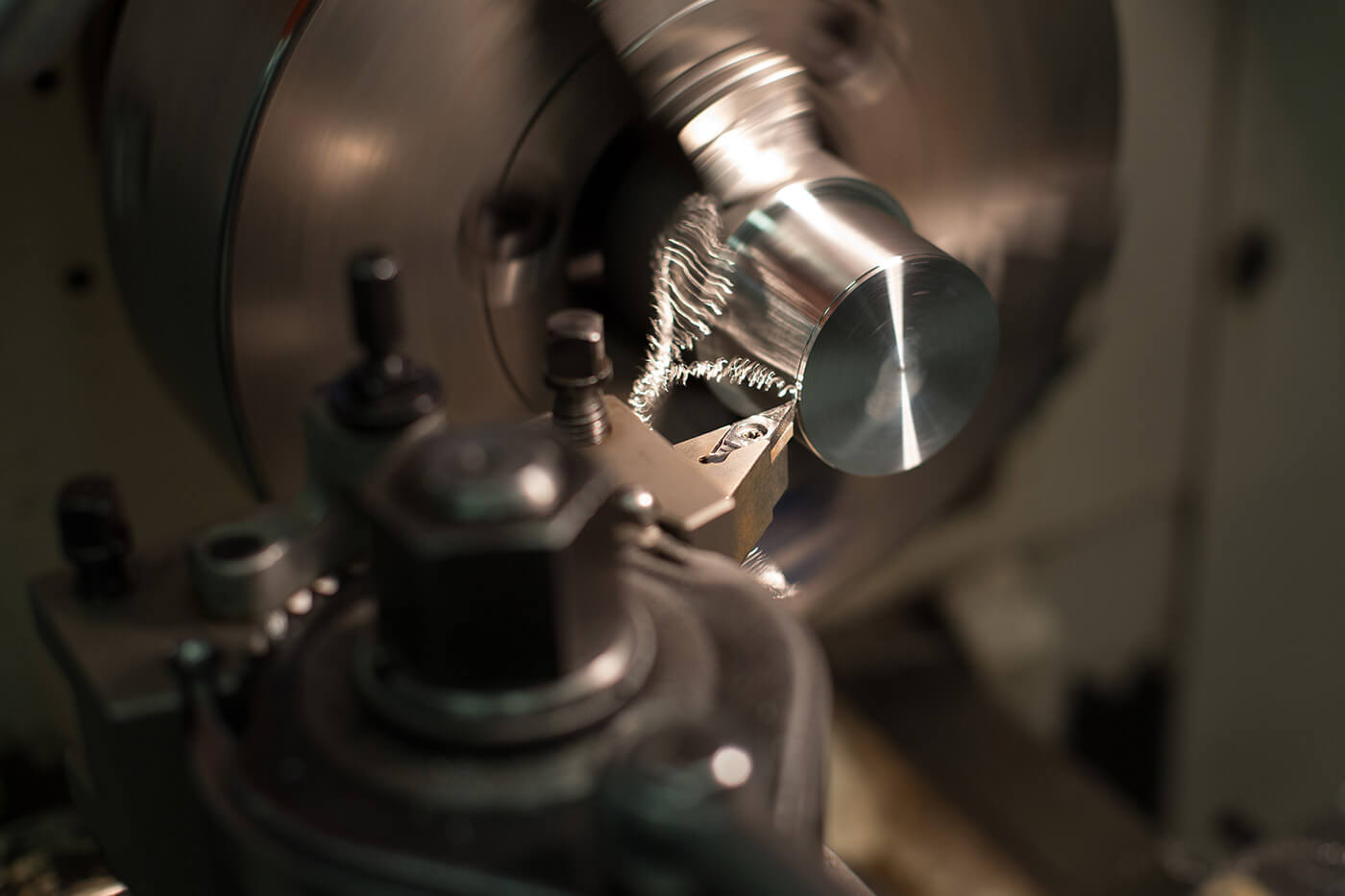

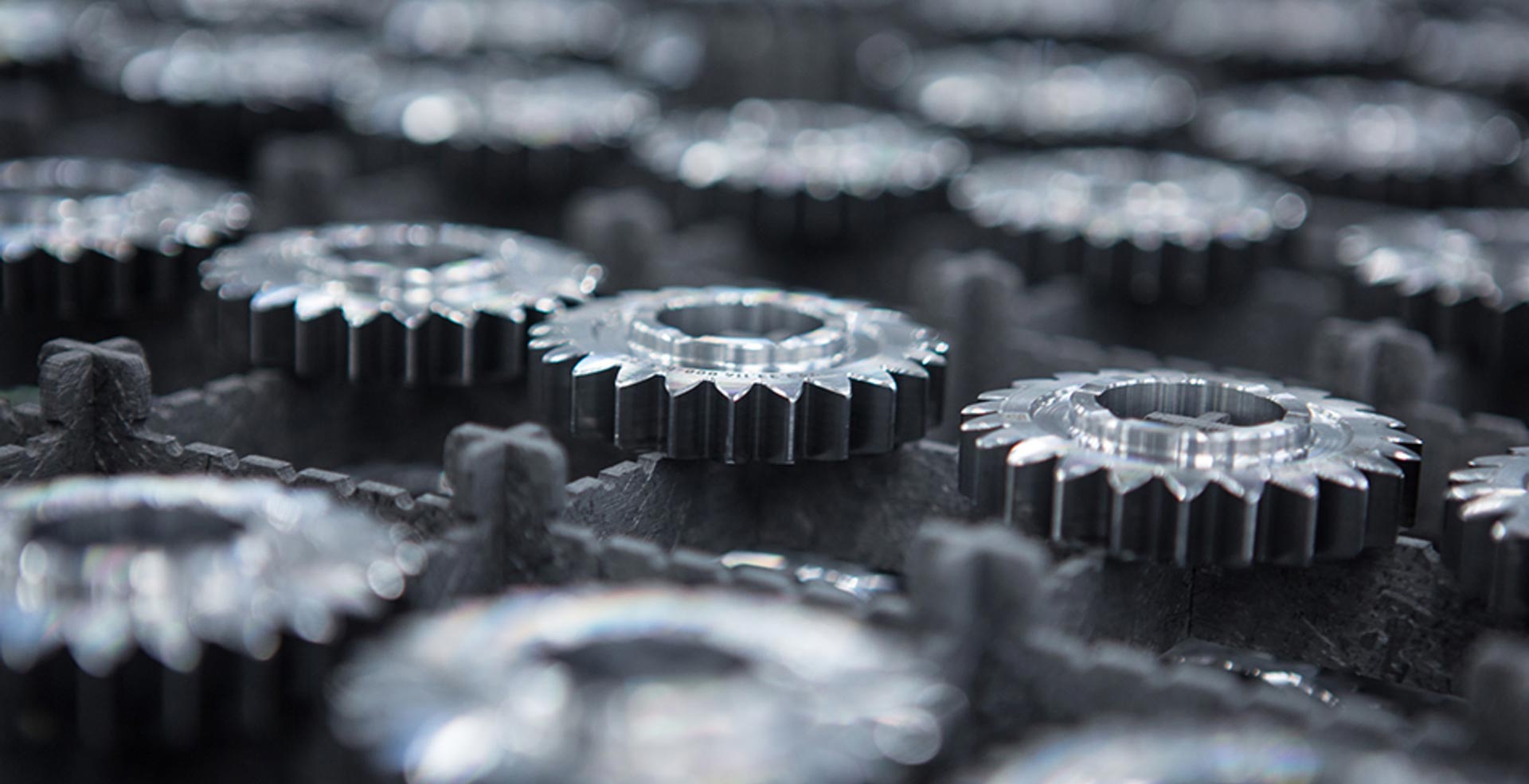

The Pankl High Performance Plant was mainly built to manufacture KTM motorcycle gears. The main components of the gear box are (shaft and gears) will be machined in highly automated turning and milling centers.

The manufacturing process starts with the rough machining of the shafts and gears in soft temper. Afterwards the parts will be vaccum heat treated (hardened) in a series of treatment chambers. The chambers are able to move on rails and can be controlled via a transport system. In this “Shuttlemodul” a transport chamber as well as a high pressure gas quench chamber a combined in one unit.

The hardened components are afterwards final machined at milling and turning centers and upon completion stored in an automated warehouse. The allocation of parts is software supported and is handled via shuttle systems. In a final step the single components are processed via an automated assembly system.

Contact:

Phone: +43 (0) 3862 33 999-0 | Fax: +43 (0) 3862 33 999-181

[email protected]