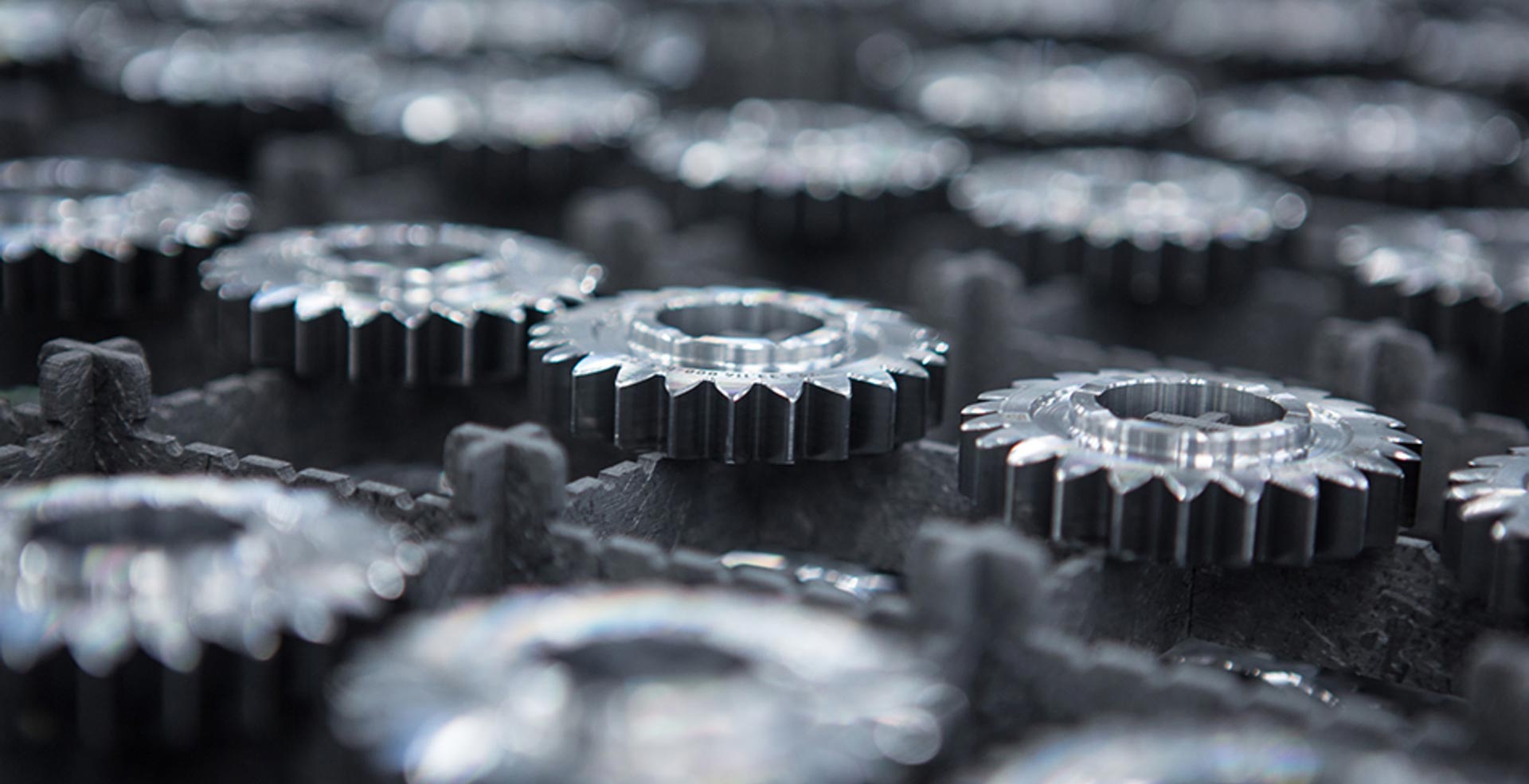

Forged parts

Our product portfolio includes forged parts for various industries, as automotive, two-wheels, truck & off-highway, aerospace and industrial application, like common-rail, connecting rod, wishbone, uprights & knuckles, triple clamps and many more.

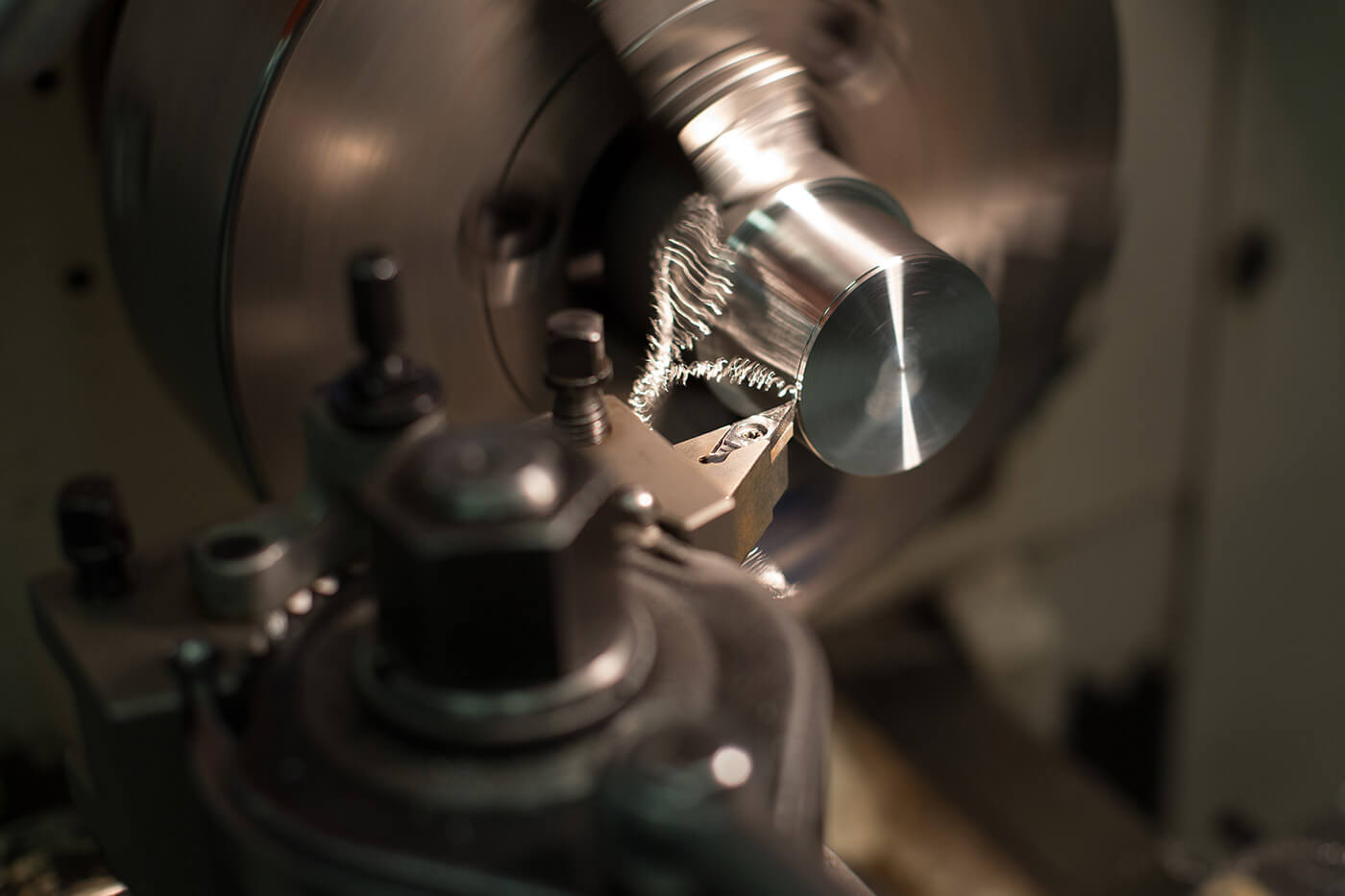

A strong process

Thanks to the perfect interaction of state-of-the-art machine tools and experienced employees.

drop forged parts

MADE IN STYRIA

Thanks to the motto: “A little bit better every day”, Krenhof is meanwhile one of Europe´s leading companies for aluminum and steel forged parts.

In their plants in Kapfenberg and Köflach, Krenhof is combining over 300 years of tradition with innovation.

More than thounsands of tones of steel and aluminum are forged per year for well-known brands out of the automotive, two-wheeler, truck & off-highway, aerospace or industrial applications.

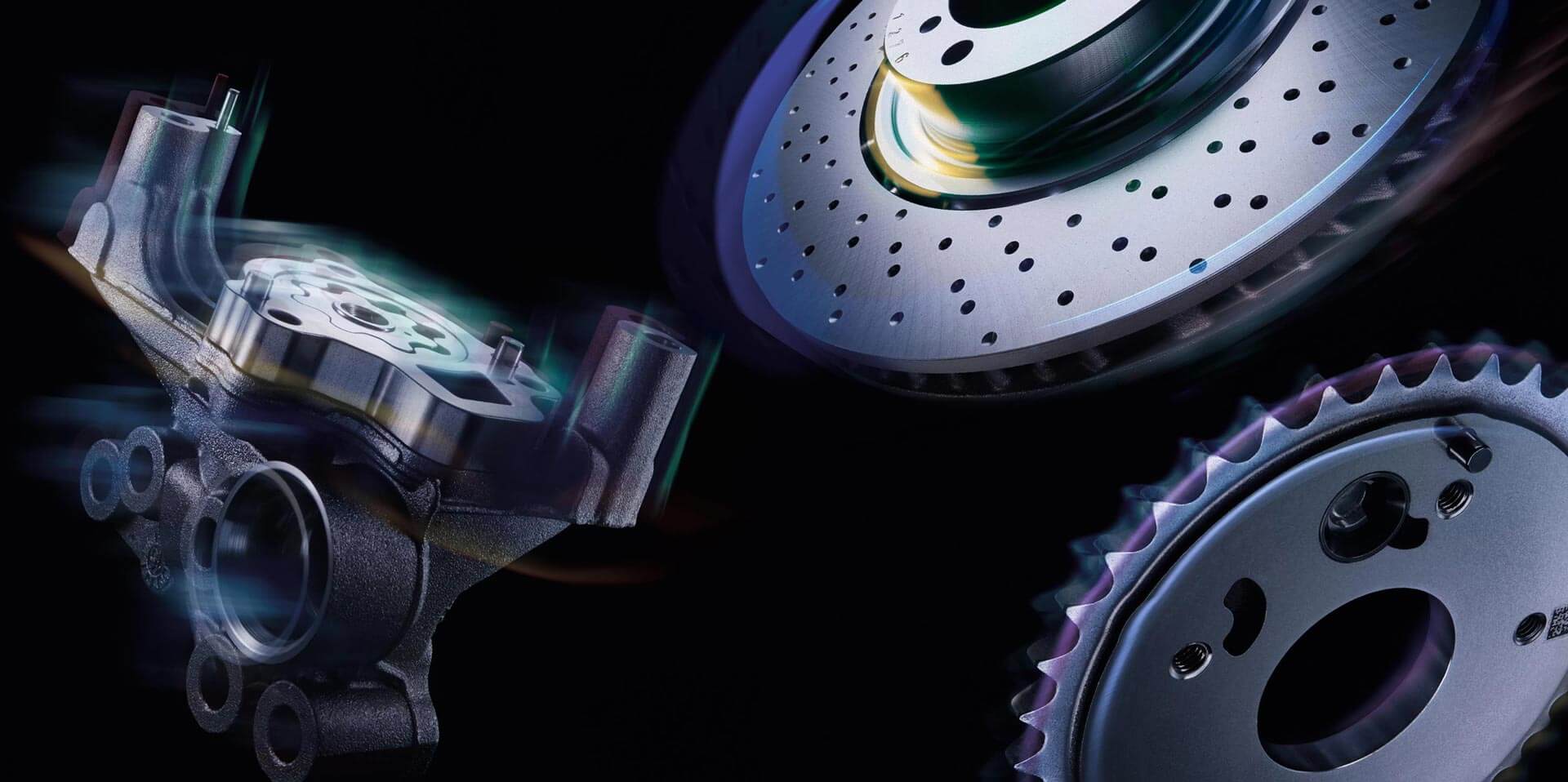

Automotive

With many years of experience in the automotive-industry, we are an established supplier for the series.

Tradition and Innovation

You can find our products in nearly every premium-vehicle. This is performance and quality at its highest level.

Wishbone

Design, validation & manufacturing of forged Aluminum chassis components. Complex shape machined and pre-assembled.

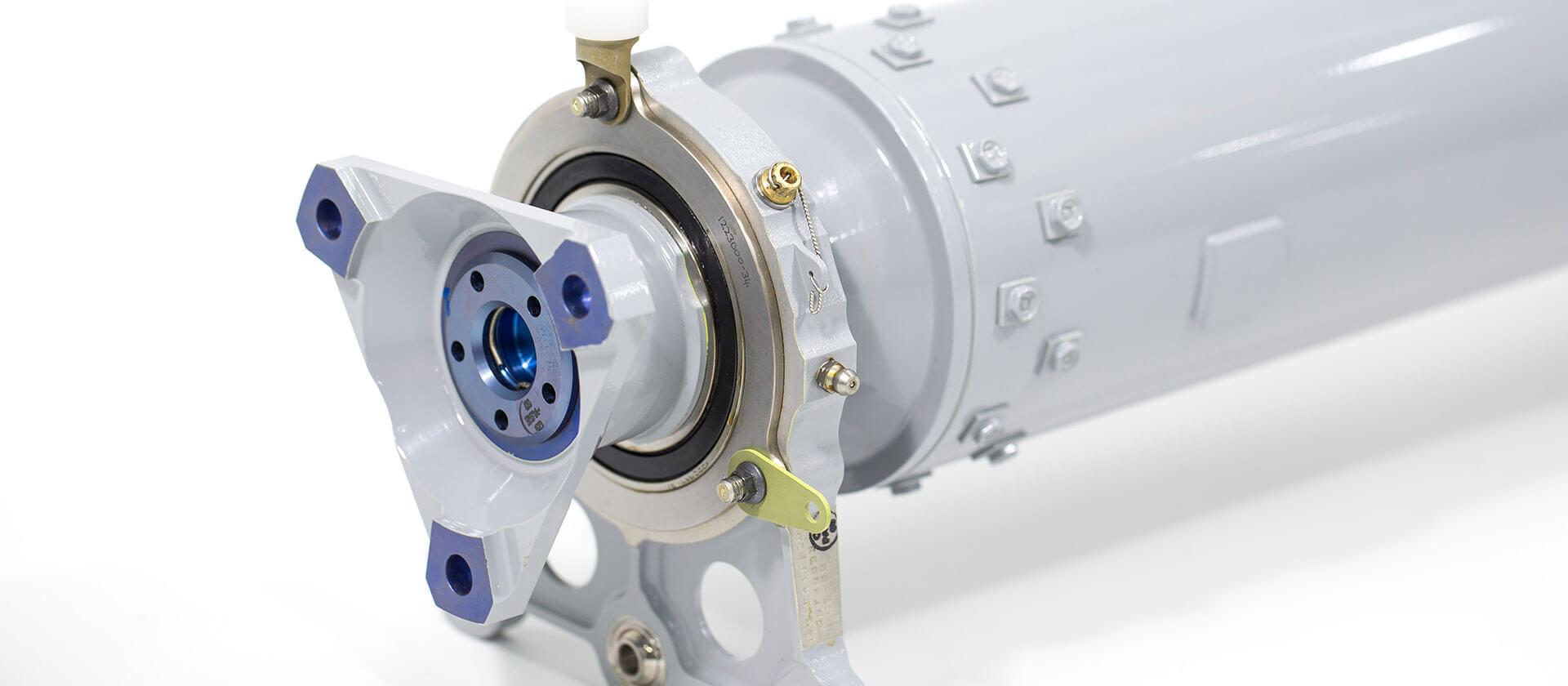

Balancer Shaft

Use in mass balancing systems of diesel and gasoline engines.

Very long geometries with requirements for the lowest possible deflection of the forged parts.

Connecting Rod

An optimal course of forged fiber in the direction of load is necessary.

Forging of ready-to-install connecting rods requires a high level of know-how in process and tool technology

Crank Mechanism

High Performance 1-cylinder crank mechanism

Uprights & Knuckles

Design, validation & manufacturing of forged Aluminum chassis components. Complex shape machined and pre-assembled.

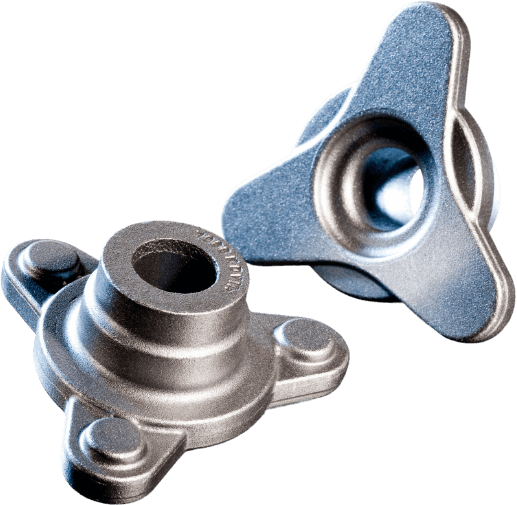

Flange short

Including their machining to the highest quality and tolerance requirements

Flange long

Including their machining to the highest quality and tolerance requirements

Uprights & Knuckles

For special applications & prototypes also folly machined and coated.

Design, validation & manufacturing of forged Aluminum chassis components. Complex shape machined and pre-assembled.

Two wheeler

You can find our aluminum and steel forged parts in well-known motorcycle-brands all around the world.

Reliable on two wheels

Thanks to our expertise in process simulation, tool development and tool making, we are able to develop and manufacture particularly competitive and process-reliable forged parts for the motorcycle industry.

Strut mount

Very complex steel forged part for motorcycle steel frames, high demands on geometry, hardening process and surface.

Triple Clamps

Forged Aluminum motorcycle components. Machined, coated & pre-assembled. Minimum weight & maximum performance.

Crankshafts

Complex geometries with ~ 9kg envelope mass with a finished weight of ~ 2kg.

Shift sleeve

Forged part mass 0.250kg, high demands on toolmaking and forming processes, small geometry transitions with high tolerance requirements. (motorcycle gearbox parts)

Truck & Off-Highway

Because our well-established production processes, we at Krenhof are able to supply our customers with high-quality-products.

Spring clamping plate

Ready-to-assemble component for truck axles, high logistical requirements.

Industrial application

Because of our manufacturing processes, we are a reliable supplier in the industrial, aerospace and medical technology sectors.

Construction industry

We can cover a wide range of parts in terms of part weight, geometry and material.

Anchor ball socket

Assembly part for formwork technology building construction. Geometrically very difficult forged part 3.7kg with an envelope mass of ~ 18kg

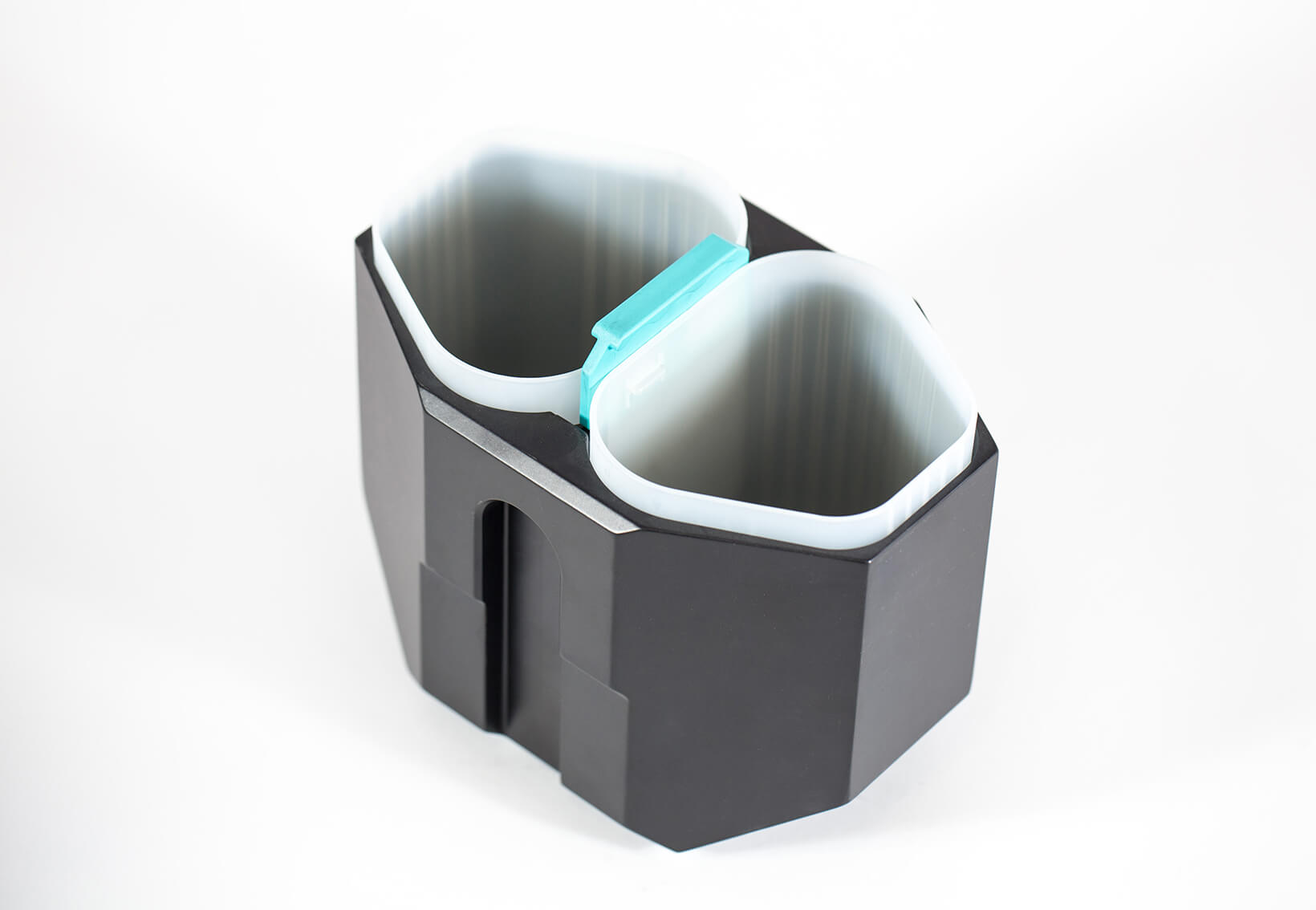

BUCKETS FOR BLOOD CENTRIFUGES

Pankl buckets for blood centrifuges, forged out of 7000 aluminum alloy series, fulfill highest standards with regards to strength, long-life cycles and reliability, withstanding heavy loads during high speed rotating daily operations

Adjusting nut

Formwork technology slab props. We can represent the entire process from forming to heat treatment (partial hardening) to thread production and assembly.

Seat Divider

Forged aerospace components, machined, coated & pre-assembled. Made from 6000 and 7000 grade Aluminums.

BUCKET FOR BLOOD BAGS

Pankl buckets for blood centrifuges, forged out of 7000 aluminum alloy series, fulfill highest standards with regards to strength, long-life cycles and reliability, withstanding heavy loads during high speed rotating daily operations.

Adjustable jaw

Formwork technology clamping system. One of the most complex forged parts with an envelope mass of ~ 34kg and a forged part mass of ~ 3kg.