Mannheim

Pankl Turbosystems GmbH

| Division | Racing |

| Technology | Machining, Additive |

| Products | Charging Systems |

| Certifications | ISO 9001 |

Pankl Turbosystems GmbH was founded in Mannheim in 2009 and is an ISO9001 certified subsidiary of Pankl Racing Systems AG.

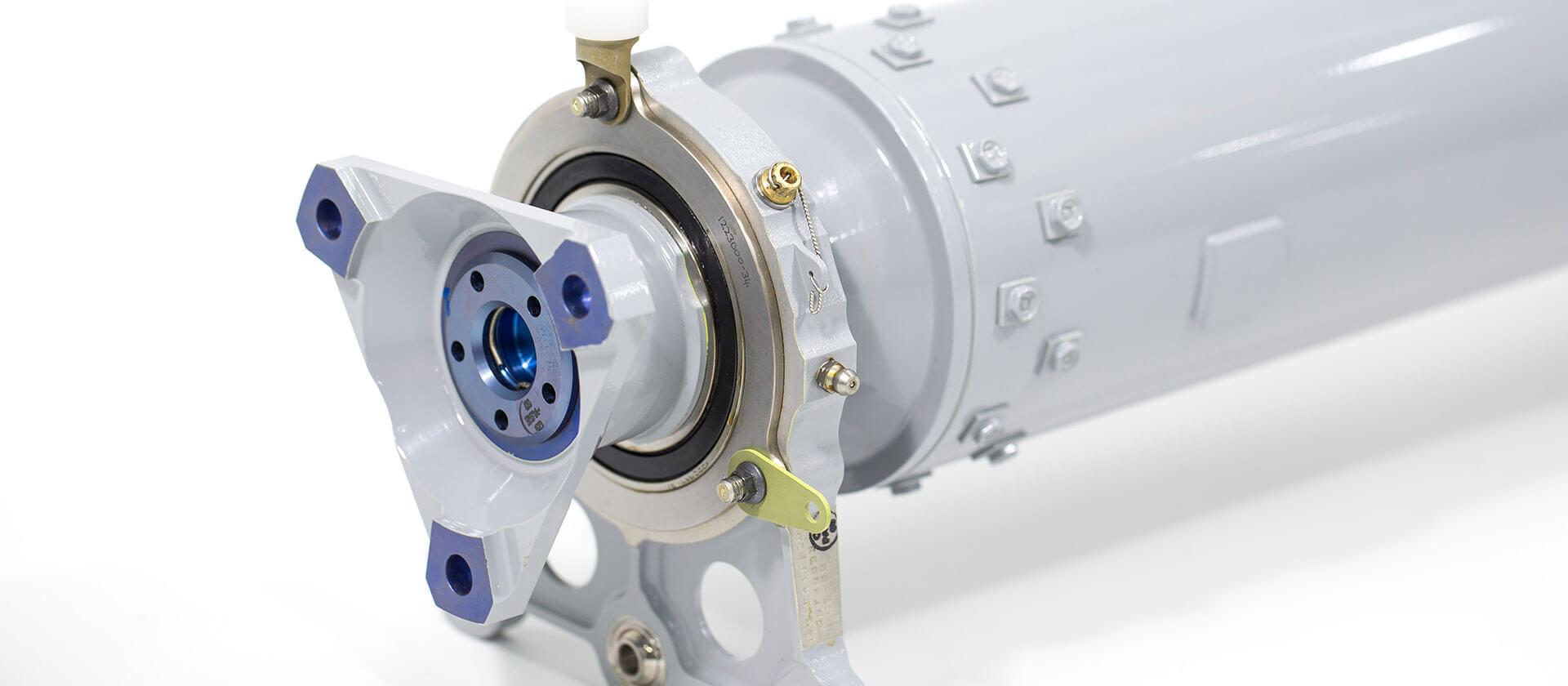

Our Site at a Glance – Corporate Video

The system competencies of Pankl Turbosystems lie in the development, testing, and production of innovative turbocharging systems for various motorsport, high performance, commercial vehicle, off-highway, aviation, and fuel cell applications. In addition to complete development, we also offer engineering services in the areas of design and simulation, as well as testing services for conventional and electrically assisted turbocharging systems. Our competencies include: state-of-the-art test facilities, hot gas test stand in combination with a battery simulator, customer-specific validation programs, assembly of advanced prototypes and small series according to the highest quality requirements.

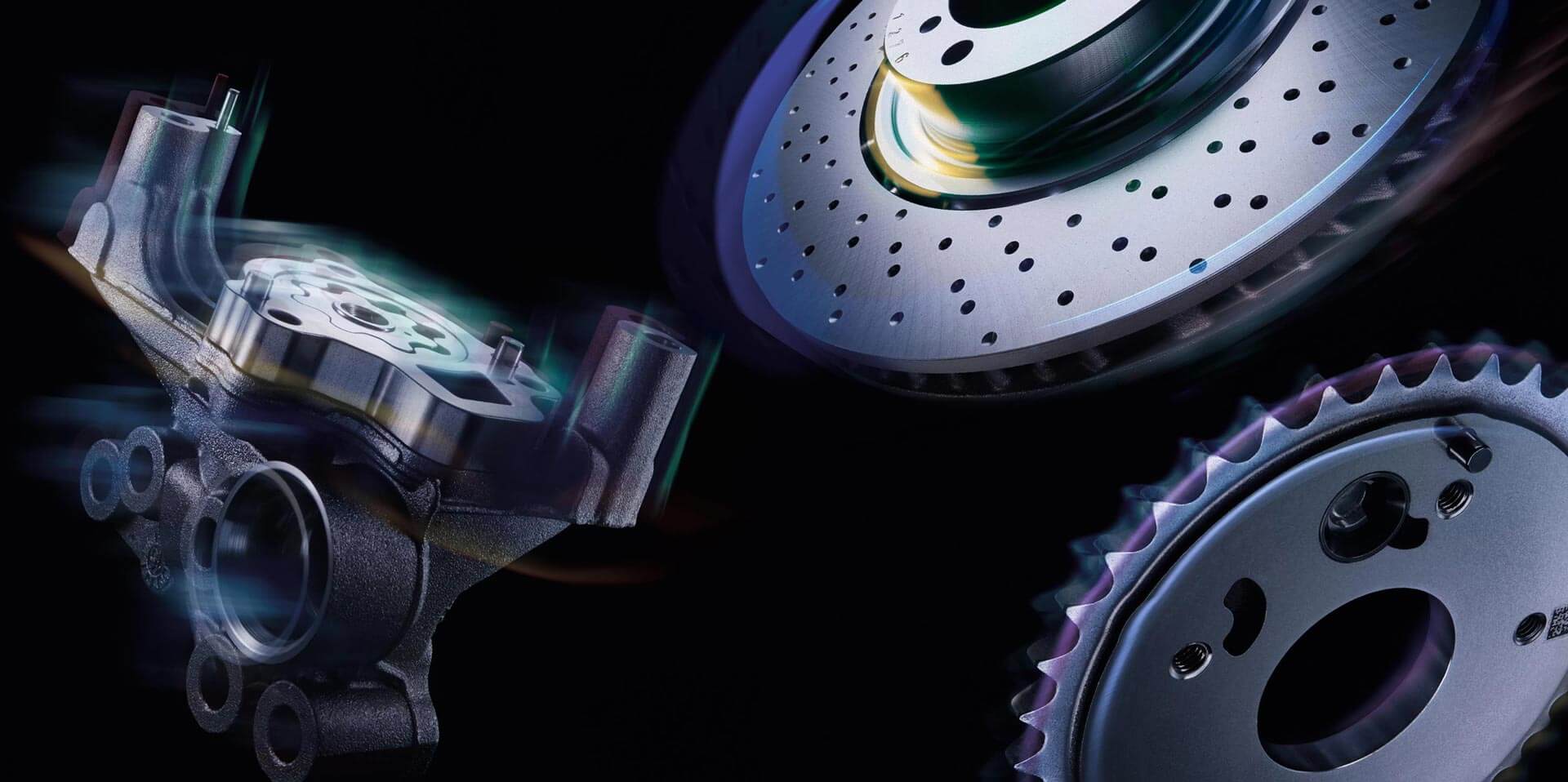

Our product portfolio

- High-performance turbochargers with wastegate or VTG control

- Multi-stage turbocharging systems

- Electrically assisted turbochargers (EAT)

- Electric compressors

- Turbo-compound generators

- Fuel cell air supply systems (FCAS)

- SiC-Inverter

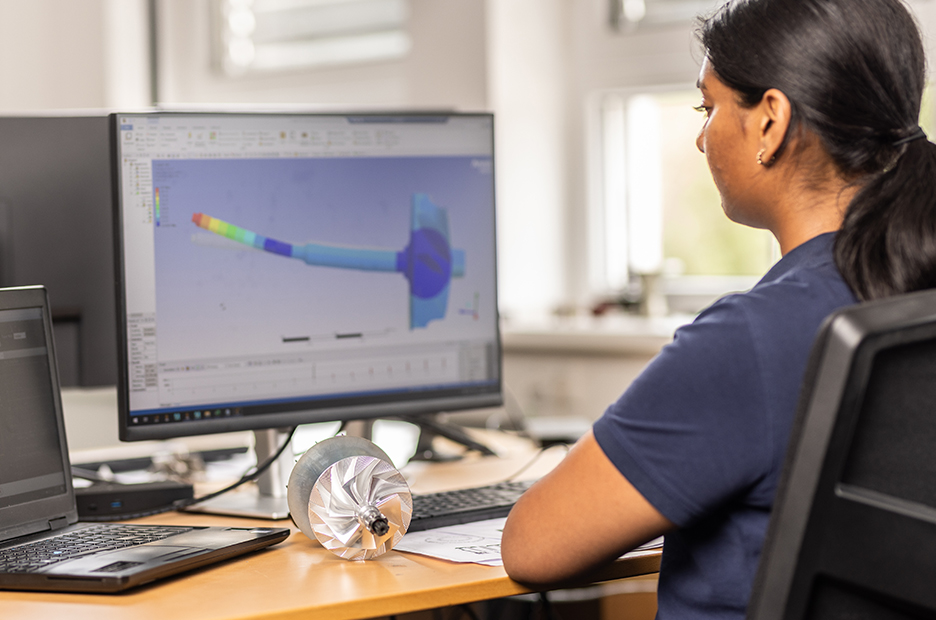

Research & development

As an innovative supplier of turbocharging systems, Pankl Turbosystems has a wide range of development competencies.

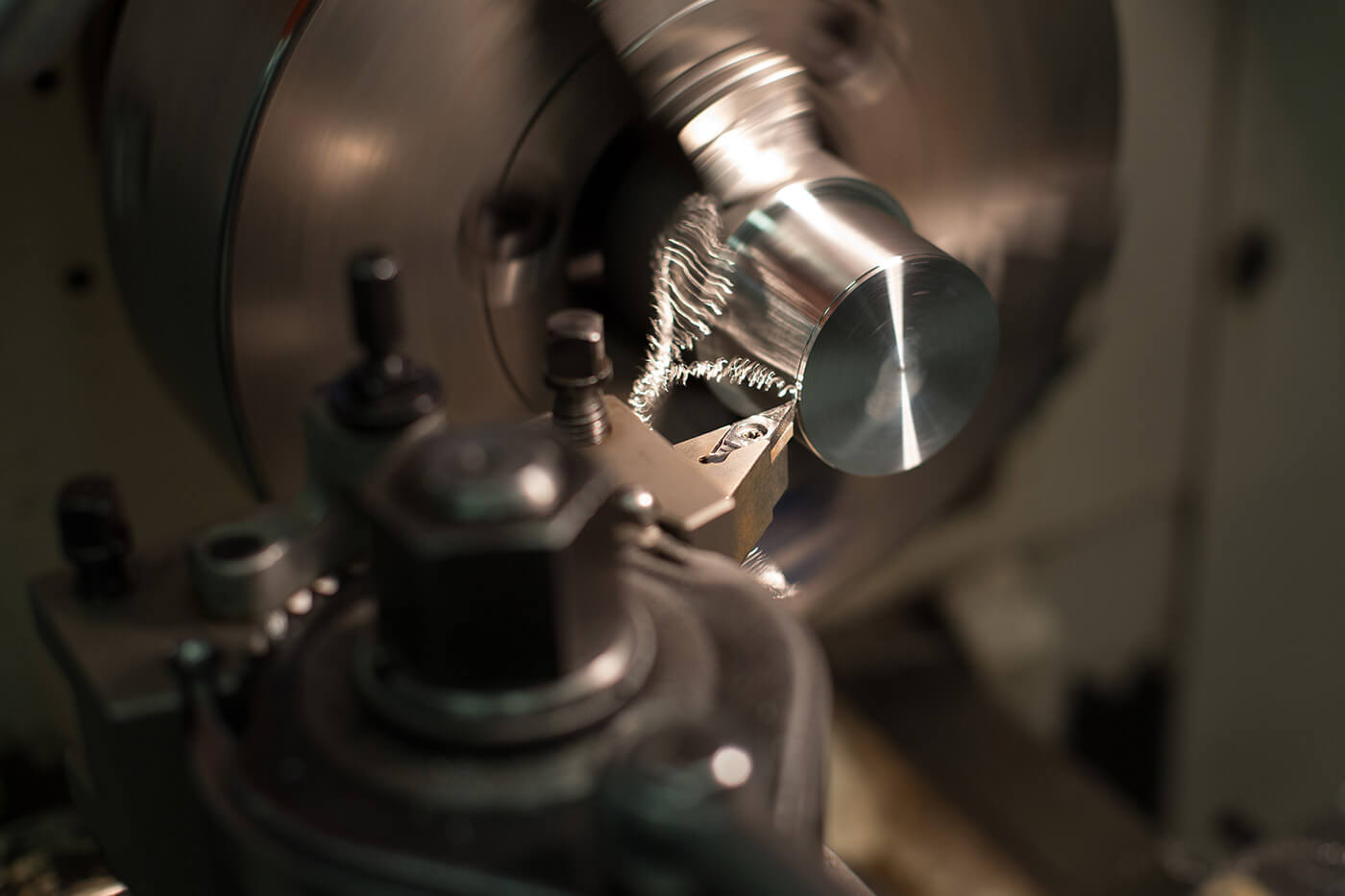

- Definition and simulation of rotating and static components

- Component and system design, including 3D, 2D and BOM generation

- Electrics and electronics (e-motors and power electronics)

- Validation on component and system test benches

System Engineering (V-Modell)

Systems engineering plays a central role at Pankl Turbosystems, approaching development with a holistic approach. This is particularly necessary for complex systems such as electric compressors or turbochargers, since a wide variety of topics such as bearing systems, fluid systems or electric drives must be integrated. Based on requirements agreed with the customer, a development process according to the “V-model” is followed, creating a distinct link from initial definition up to the Design Verification Plan (DVP).

Our Development Overview

Assembly

Turbochargers, fuel cell air-supply (FCAS) and electrically assisted turbochargers (EAT) systems are commissioned using out ERP system, guaranteeing 100% traceability of each component. Our assembly process is characterized by flexible adaptation to customer requirements and quantities, optimized based on many years of industry experience.

- Prototype and small series assembly

- Quantities up to 10,000 units

- ERP-guided parts management

- Single part and operational balancing

- Integrated quality inspection steps

Quality

Pankl Turbosystems’ highly developed and integrated quality management system ensures our products meet the high level of reliance our customers place in us. All relevant processes are approved by our customers and by certification bodies (ISO 9001) and are regularly reviewed and improved. We have the possibility of material testing in our own laboratory and non-destructive material testing according to all common methods.

Every product is tested by us so that system-relevant parameters can be traced at any time.

- Balance quality of individual or system components

- Field strength measurement of rotors

- Determination of electromagnetic constants during operation

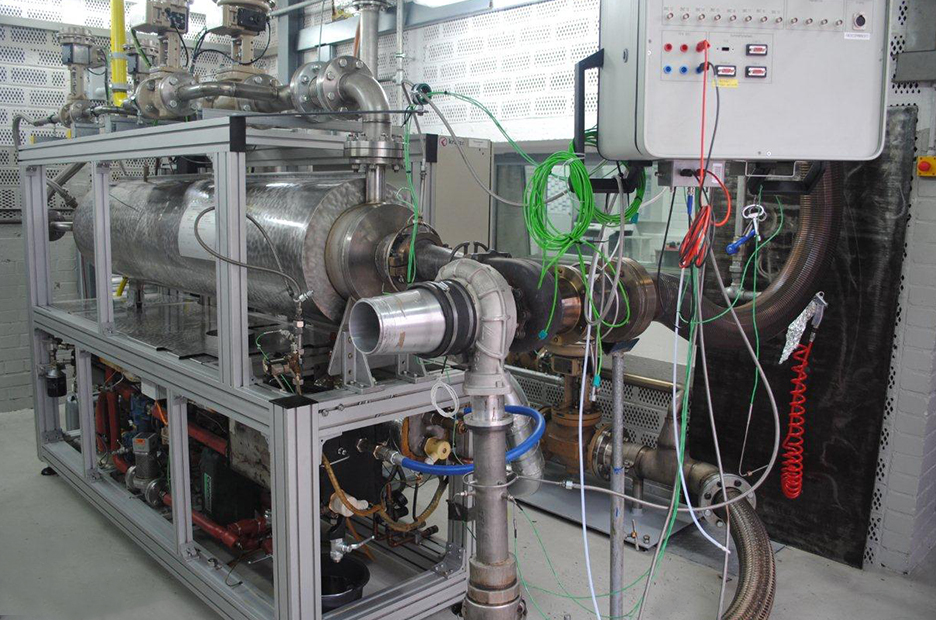

Testing

Pankl Turbosystems offers a comprehensive range of testing services in the field of induction systems, ranging from customer-specific individual tests to complete validation programs. Our equipment includes three test stands for conventional as well as electric induction systems. Each are adapted to specific validation requirements and equipped with special equipment such as a compressor closed loop unit. Further individual component test benches are available, such as an air bearing test bench for mapping different load spectra.

Specification of the test benches

- Thermodynamic measurement (Compressor and Turbine maps)

- Extended turbine map measurements in CCLU (Compressor Closed Loop Unit)

- Functional tests for electrically assisted induction systems with battery simulator

- Automated endurance tests according to specified load cycles

- Rotor Dynamics / shaft motion measurements

- Acoustic and vibration measurements

- Thermal shock tests

- High-cycle fatigue tests, including optical tip timing of turbine and compressor blade vibrations

- Burst & containment tests

- Material tests for turbochargers, exhaust manifolds, exhaust systems

- Functional tests for wastegates / VTGs / actuators

CAREER

Looking for a job?

JOBS at pankl turbosystems

Manuel Kindinger-Ding

Director Sales

Telefon: +49 171 2287 022

E-Mail: [email protected] or [email protected]

Adrien Kopp

Director Innovation

Gerhard Krachler

Managing Director